Understanding Cold Climate HVAC Design

A cold climate is defined as an area with a mean winter temperature of 32°F or below. In such regions, the design and performance of HVAC systems must be tailored to withstand extreme temperatures and harsh conditions.

Engineers should seek information from ASHRAE – the leading authority on HVAC design in cold climates. The ASHRAE Cold Climate Design Handbook offers guidance for engineers, covering everything from system design to equipment selection. It emphasizes the importance of proper insulation, efficient heating sources, and minimizing air infiltration to ensure optimal performance in extreme temperatures.

This article will highlight some of the ASHRAE recommendations for HVAC cold climate design and dive into the important role of coil freeze protection.

The Role of Coil Freeze Protection in Cold Climate Design

Coils are an integral part of any HVAC system, responsible for transferring heat or cooling from the air into the building.

Steam Coils

Steam coils are another important component in cold climate HVAC design. These coils are used to heat air in the system, and they are particularly useful in cold climates where the outdoor temperature is consistently below freezing.

Steam coils are another important component in cold climate HVAC design. These coils are used to heat air in the system, and they are particularly useful in cold climates where the outdoor temperature is consistently below freezing.

Steam coils work by using steam from a boiler to heat the air passing through the coil. This heated air is then distributed throughout the building to maintain a comfortable indoor temperature. In cold climates, steam coils are often used in conjunction with other heating methods, such as hot water coils or electric heaters, to provide efficient and effective heating.

Hot Water Coils

Hot water coils are another common component in cold climate HVAC design. These coils use hot water from a boiler to heat the air passing through the coil, similar to steam coils.

Hot water coils are another common component in cold climate HVAC design. These coils use hot water from a boiler to heat the air passing through the coil, similar to steam coils.

In addition, hot water coils can also be used in conjunction with glycol to prevent freezing in the system. By using a mixture of water and glycol in the hot water coil, designers can ensure that the system will continue to function even in extremely cold temperatures. There are considerations for using glycol in a system, such as environmental concerns and energy penalties.

Chilled Water Coils

While heating is the primary concern in cold climate HVAC design, cooling is also an important consideration. Chilled water coils are used in HVAC systems to cool air.

Chilled water coils work by using cold water to cool the air passing through the coil. This cooled air is then distributed throughout the building to maintain a comfortable indoor temperature.

The Cost of Frozen HVAC Coils

In cold climates, HVAC system components are at a greater risk of freezing, which can lead to reduced efficiency and even system failure. This is where coil freeze protection becomes crucial. Frozen coils can lead to costly repairs or even the need for complete coil replacement.

Costly Repairs and Replacement: The physical damage caused by frozen coils can be extensive. The expansion of freezing water can cause the coils to crack or rupture, necessitating costly repairs or even complete coil replacement.

Secondary Damage: The problems don’t stop at the HVAC system. When a ruptured coil thaws, it can lead to water damage in your building, damaging walls, ceilings, and potentially important equipment equipment. Any resulting downtime can disrupt business operations, leading to lost revenue and productivity.

Increased Insurance Premiums: If you experience water damage from a ruptured coil, it might also lead to increased insurance premiums. Insurance companies often raise rates following claims, meaning a frozen coil could impact your bottom line for years to come.

Overview of Freeze Protection Strategies as Recommended by ASHRAE

Understanding aspects of cold climate freeze protection and air stratification is key to designing efficient, reliable HVAC systems.

Freeze Protection

- Use of Antifreeze Solutions: When hydronic fluids are exposed to outdoor air, antifreeze solutions such as glycol mixtures can be used to prevent freeze-ups.

- Strength of Glycol Mixtures: The strength of the glycol mixtures should be sufficient relative to the climate zone to prevent the fluid from freezing.

- Mixed-Hydronic Systems: Use mixed-hydronic systems for building heating. Hot water can be circulated for hydronic radiation terminal equipment, while heating glycol can be generated via a heat exchanger for AHU coils or other outdoor-exposed equipment.

- Recirculating Pumps: In mild climates or where mixed air temperatures reduce the chance of freezing, providing a pump for constant water flow through the coil may help to prevent freezing.

- Chilled-Water Coils: Chilled-water coils used for cooling purposes must have isolation valves, drains, and vents for flushing and drainage before cold conditions.

- Control Safeties: For water-based coils, use control safeties such as freezestats downstream of the coil to identify freezing conditions and shut down the unit to protect the coil.

Air Stratification

- Stratified Airstreams: Cold outdoor air mixed with warm return air tends to remain stratified. This can freeze the bottom of water coils and trigger nuisance freeze stat alarms on glycol coils.

- Encourage Mixing: Use strategies like positioning dampers and using air blenders or mixers to help reduce stratification.

- Temperature Sensors: Place temperature sensors downstream of a blender for more consistent and accurate temperature readings. But keep in mind that this requires notable upstream and downstream distance, which should be considered early during the layout of air-handler spaces.

Considerations on Coil Freeze Protection

ASHRAE, recommends a variety of freeze protection measures, including the use of glycol mixtures and control safeties like freezestats. While these recommendations are based on solid knowledge and expertise, it’s important to remember that every solution has its pros and cons.

For instance, glycol mixtures can indeed lower the freezing point of the heat transfer medium, but they also reduce the efficiency of the system and increase energy consumption due to the additional pumping required. Plus, the use of glycol often necessitates larger system infrastructure to compensate for the differences in heat transfer performances. And let’s not forget that glycol may not be effective in extreme temperature ranges and it comes with ongoing maintenance and refill costs. For more information on the true cost of glycol and it’s considerations, you can read more here.

Other strategies like freeze stats and recirculation pumps have their limitations too. Freeze stats can result in nuisance trips and increased downtime, while recirculation pumps may not run frequently enough to be effective and require routine maintenance. They also do not provide protection in the event of a power failure.

While ASHRAE’s recommendations provide a solid foundation, it’s important to understand the limitations and consider other advanced solutions such as Cooney Freeze Block™ Coils to ensure optimal performance and reliability of your HVAC systems in cold climates.

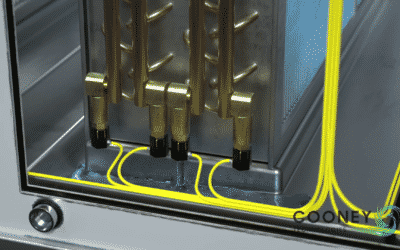

Freeze Block Coils: Designed for Commerical and Industrial HVAC Systems in Cold Climate

That’s why at Cooney Engineered Solutions, we’ve developed Cooney Freeze Block™ Coils as a reliable and efficient solution for preventing frozen coils. These coils have an expansion relief header and a relief valve that releases a controlled volume of fluid when the coil freezes, designed to prevent coil rupture. The technology is engineered to operate and function the same as a traditional coil, with minimal impact on coil dimensions. We also offer the Smart Coil System which provides real-time freeze alert monitoring and alerts to maintenance personnel which can be tied into a building automation system.

That’s why at Cooney Engineered Solutions, we’ve developed Cooney Freeze Block™ Coils as a reliable and efficient solution for preventing frozen coils. These coils have an expansion relief header and a relief valve that releases a controlled volume of fluid when the coil freezes, designed to prevent coil rupture. The technology is engineered to operate and function the same as a traditional coil, with minimal impact on coil dimensions. We also offer the Smart Coil System which provides real-time freeze alert monitoring and alerts to maintenance personnel which can be tied into a building automation system.

While other freeze protection strategies certainly have their place, we believe that Cooney Freeze Block™ Coils should be the top consideration for cold climates. They come backed by a 30-month freeze protection guarantee, can reduce the need for glycol in some cases, while offering peace of mind.

Coil Freeze Protection Methods

Ultimately, the goal is to design an HVAC system that not only performs efficiently but also reliably even in the harshest of conditions. In addition to ASHRAE’s recommendations, engineers should also consider factors such as maintenance costs, energy consumption, system infrastructure, and long-term effectiveness when deciding on a coil freeze protection method.