Imagine having a frozen – or worse, a ruptured coil above a critical area in your facility. Unfortunately, we’ve seen this happen and happen often in places like hospitals, pharmaceutical R&D, and manufacturing plants.

Imagine having a frozen – or worse, a ruptured coil above a critical area in your facility. Unfortunately, we’ve seen this happen and happen often in places like hospitals, pharmaceutical R&D, and manufacturing plants.

In the most extreme case, we’ve seen a frozen coil split, thaw and then flood. Decommissioning an operating room and destroying an MRI machine in a hospital – mounting to a whopping 9.3-million-dollar insurance claim.

Plan for the Worst, Hope for the Best

If you are a facilities engineer in healthcare, pharmaceuticals, or other critical facility you know you must plan for the most extreme scenarios and hope for the best.

![]() That’s why facilities across North America demand the best in coil freeze protection to keep their building operating 24/7/365.

That’s why facilities across North America demand the best in coil freeze protection to keep their building operating 24/7/365.

While glycol and freeze stats are historically used for freeze protection, they aren’t without their flaws. Freeze stats are often seen as nuisance alarms and sometimes never even connected! Glycol can be a great freeze protection option in some cases but costs a lot in energy and maintenance while also posing environmental concerns when used in an open-loop system.

Necessity is the mother of Invention

Over a decade ago, an emergency call at a large pharmaceutical R&D campus with multiple frozen HVAC coils sparked the idea for Freeze Block coils. Where the coils had frozen and split was in a particularly critical area of the campus. Expensive equipment and years of product development experiments were at risk. As a coil replacement rep firm, we were challenged to find a solution to stop these coils from rupturing again.

Noticing the lack of eco-friendly and reliable freeze protection, our team set out to develop Freeze Block Technology. Freeze Block HVAC coils allow critical facilities to get up and running quickly after a freezing event or malfunction.

A Smarter Option

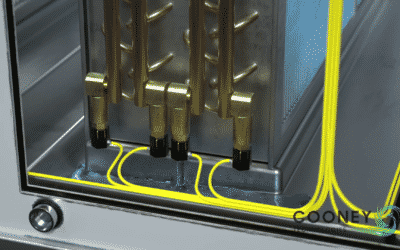

Freeze Block HVAC coils use patented pressure and temperature relief valves to automatically sense a freezing event. The coils then are set to discharge a controlled volume of fluid and reseat to allow the coil to freeze without rupturing.

When paired with the Cooney Smart coil, this discharge sends a signal to your building automation system and can be programmed to shut down fans, close outside air louvers, and alert your facility of the potential issue. Once the coils are thawed, they can go back into working operation.

Adding Freeze Block & Smart Coil to your critical facility is a no-brainer. Contact our team today to learn more!

Want to Learn More about Freeze Block?

Looking to learn more about Freeze Block Technology for and application in your critical facility? Our team is ready to answer your questions.