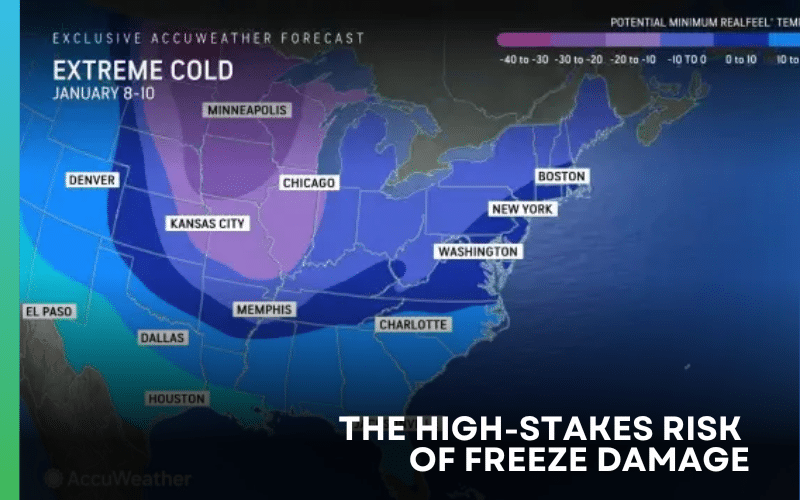

Selecting the right fluid and steam coil freeze protection for your HVAC system is crucial in safeguarding your facilities against winter’s harsh conditions. With the right solution, you can prevent damaged HVAC coils, facility damage, and expensive repairs.

In this article, we compare two popular solutions—Coil Freeze Plugs and Freeze Block Coils—to help engineers, facility managers, and contractors make an informed decision. We will assess these options based on how they work, maintenance requirements, flood risk, and warranty comparison.

dHow do HVAC coil freeze plugs work?

Coil Freeze Plugs utilize rupture caps that are brazed onto the return bends. These caps burst when the coil freezes from the center toward the return bends, allowing water to escape. Pressure sensing will not protect freezing that occurs from the outer edges to the center of the coil.

While this can prevent immediate damage to the coil, it exposes the facility to potential flood-related damage.

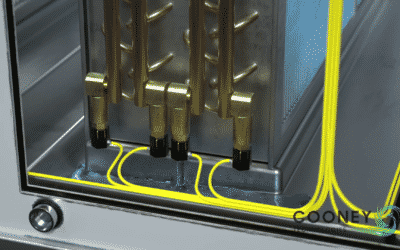

How does Freeze Block technology work?

Freeze Block Technology, like Cooney’s Freeze Block™ Coils, utilizes both temperature and pressure sensing. The Freeze Block valve senses a change in temperature or pressure and activates a valve to displace a controlled volume of water. The valve reseats, allowing the coil to return to normal operation without requiring significant downtime once thawed.

Key Takeaway: While Coil Freeze Plugs rely solely on pressure sensing and result in open ports upon activation, Freeze Block Coils offer a more comprehensive protection approach by using both temperature and pressure sensors, which minimizes water discharge and allows the coil to resume normal operations post-thawing.

Risk for Building Flooding and Damage

Coil Freeze Plugs

With Coil Freeze Plugs, once the rupture caps burst, multiple open ports allow water to escape freely, presenting a high risk of significant water loss and facility damage. This can result in extended downtime and costly repairs.

Freeze Block Coils

Freeze Block Coils are designed to displace a controlled volume of water upon activation, reducing the risk of significant water loss or facility damage. The valve reseats after the freezing event, allowing the coil to return to normal operation without flooding the facility.

Freeze Block Coils are designed to displace a controlled volume of water upon activation, reducing the risk of significant water loss or facility damage. The valve reseats after the freezing event, allowing the coil to return to normal operation without flooding the facility.

Key Takeaway: Freeze Block Coils offer better protection against facility flooding and water damage compared to Coil Freeze Plugs.

Maintenance

Coil Freeze Plugs

Maintenance for freeze plugs can be labor-intensive. When rupture caps burst, they need to be located, and replaced, and the coil must be isolated and drained. This can be a challenge for facilities where space is tight and downtime is not an option. Predicting the number of caps that may be stretched but not yet compromised is challenging, increasing the risk of future failures and additional repair needs.

Frequent bursting and replacement of rupture caps can weaken the overall integrity of coil freeze plugs over time. Missed or compromised caps further reduce their durability, increasing the likelihood of future failures.

Freeze Block Coils

Freeze Block™ technology is designed for minimal maintenance. The valve reseats after activation, maintaining the integrity of the coil and reducing the need for repairs or downtime.

Freeze Block Coils maintain high integrity even after multiple activations. Their design ensures consistent performance and durability, significantly reducing the risk of future failures.

Key Takeaway: Freeze Block Coils require significantly less maintenance and a longer life span than Coil Freeze Plugs, as they do not necessitate frequent replacements or extensive repair work.

Warranty Comparison

Coil Freeze Plugs

The warranty for Coil Freeze Plugs typically covers only a portion of the coil, leaving some areas unprotected and potentially increasing repair costs.

Freeze Block Coils

Freeze Block Coils come with a comprehensive 30-month warranty that covers 100% of the coil, providing peace of mind and ensuring complete protection.

Key Takeaway: Freeze Block Coils offer a more comprehensive and reliable warranty compared to Coil Freeze Plugs.

Conclusion

Freeze Block Coils provide superior coil freeze protection, minimal maintenance, reduced risk of flooding, and a more comprehensive warranty. For engineers, facility managers, and contractors looking for a reliable and efficient freeze protection solution, Freeze Block Coils are the recommended choice.

Actionable Advice: If you are considering upgrading to HVAC coils with freeze protection, consult with a heat transfer specialist to evaluate the specific needs of your facility and ensure you choose the most effective solution. For expert guidance and to explore the benefits of Freeze Block Coils, book a call with our team today.