Cooney

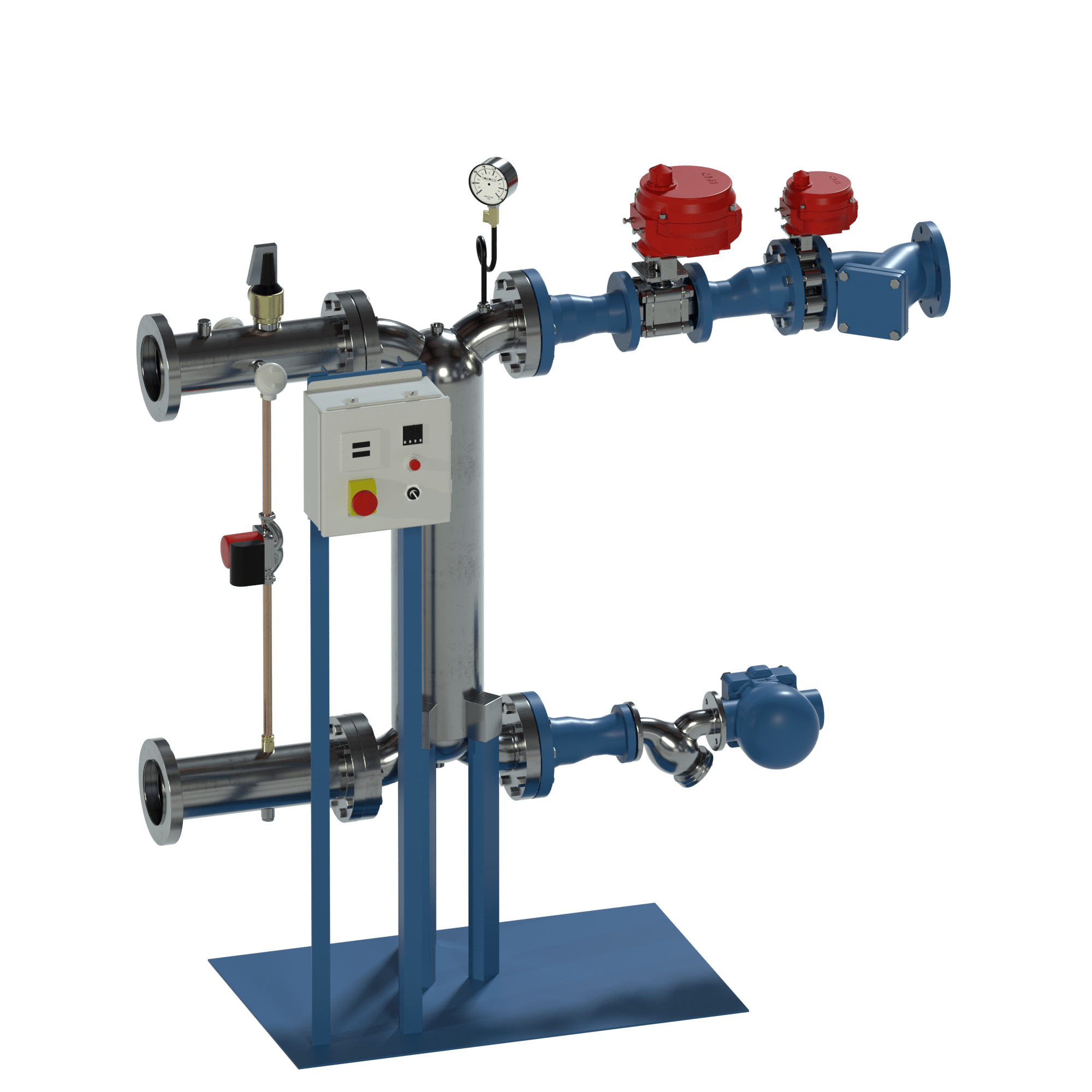

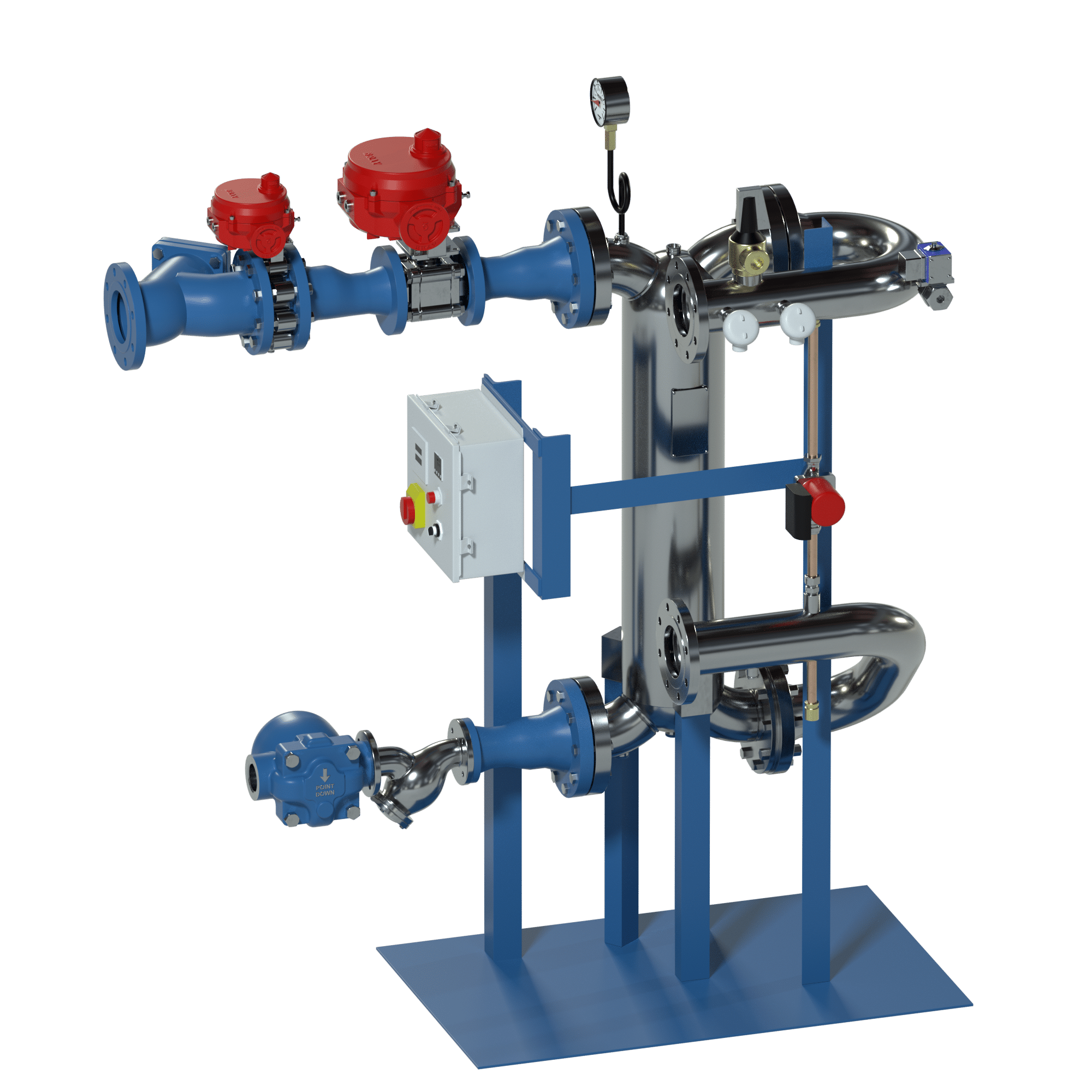

Thermo-Pack

Steam to Domestic Hot Water Heat Exchanger

Ultra-efficient steam to domestic hot hater heat exchanger. The Cooney Thermo-Pack’s sub-cooling design can help increase efficiency and reduce energy costs in a compact vertical footprint.

System Benefits

- Condensate sub-cooling to temperatures of 110°F

- Corrosion-resistant heat exchanger with complete welded structure

- Eliminates dangerous flash steam

- V-Ball control valve standard with 300:1 turn down for precise control and energy savings

- Small foot print and vertical design fits into small mechanical rooms

Standard Components

- 316L Stainless Steel Shell & Coil Heat Exchanger

- Control Panel included for ease of operation an system feedback

- V-Ball Control Valve with 100-1 turn down. Can accommodate up to 130LB steam without the need of a steam pressure-reducing station

- Pressure / Temperature Relief Valve

- Inlet Y-Strainer

- Recirculating Pump

- Painted Carbon Steel Base Plate and Frame

- Available in: 15, 30, 60 GPM

- Additional sizes available for custom units

Skid Dimensions

Have a small mechanical room or small elevator you need to get the skid through? We can customize that for you!

Learn about our custom domestic heat exchanger skids.

Energy Savings

Annual Savings of a Domestic Thermo-Pack Compared to a Shell & Tube Heat Exchanger*

*Based on steam pressure of 15 PSIG, 30 GPM, 10 hours of use per day, and $25 cost per therm*

Interested in calculating your facility’s ROI? Contact us today for your own energy analysis.

Custom Heat Exchanger Solutions

Sick of catalog units?

Want a plug-and-play heat exchanger with the latest technology?

The Cooney Thermo-Pack is for you.

At Cooney Engineered Solutions we know that one size does not always fit all and that is why we offer custom, one-of-a-kind solutions for unique projects. We will engineer the Cooney Thermo-Pack with you to fit your specific application and requirements.

Skid Dimensions

Need to fit into limited existing space? We can adjust the skid dimensions to conform to locations with restricted space.

Base Plate & Frame

Optional 316L SS base plate and frame.

Control Valve / Package

Variety of control options available per facility’s specifications and requirements. Up to 300:1 turndown control available. Pneumatic control valves also available.

Blending Station

Combat the risk of Legionella by increasing hot water discharge temperature and then blending cold water to the desired temperature.

Pressure Motive / Pump Traps

Gravity condensate drainage standard. Pump traps are available if condensate needs to be lifted.

Outlet Orientation

We can adjust outlets to best fit your application making them easily accessible and saving you installation costs.

Steam Shut Off Safety Valve

Available for an added level of steam safety protection.

Equipment Elevations

For areas with restricted head room, we can usually adjust equipment elevations to fit your space.

Comprehensive Service: From Consultation to Start-Up!

All Cooney Thermo-Packs can be customized to fit your specific application including elevations, piping, materials, components, and more. Cooney Engineered Solutions will be there for you throughout the entire process including:

- Consultation

- Initial Site Visit

- Customization

- Design

- Construction

- Start-Up

Improve Efficiency & Reduce Energy Costs With the Cooney Thermo-Pack Domestic Heat Exchanger

Are you looking to upgrade your domestic hot water heat exchanger? Look no further than the Cooney Thermo-Pack! Our design is one of the most efficient and compact choices on the market. The domestic hot water heat exchanger boasts improved efficiency, reduced energy costs, minimal maintenance interventions, and superior quality.

The Thermo-Pack domestic heat exchanger is your ideal solution for reducing operational costs while maintaining high efficiency. Boasting greater thermal conductivity, reliability, and performance than traditional heat exchangers, this innovative system not only reaches temperature changes faster but also produces fewer problems, resulting in improved energy efficiency and lower operating expenses! Additionally, its compact vertical footprint and packaged design provides easy installation.

Need to Replace Your Domestic Hot Water Heat Exchanger?

The Cooney Thermo-Pack domestic heat exchanger is the perfect choice when you need to replace a standard steam to hot water heat exchanger unit. Featuring unparalleled efficiency and performance, our DWH heat exchanger helps you save on energy costs as well as reduce upkeep over time. With its greater thermal conductivity, reliability, and corrosion resistance, it has become the go-to option for clients around the world.

Why Trust Our Experts for Your Domestic Hot Water Heat Exchanger?

At Cooney Engineered Solutions, we understand that having a reliable and efficient steam to hot water heat exchanger is of the utmost importance. That’s why our team is committed to providing you with only the highest quality heat exchangers. With decades of experience in heating applications and an unparalleled dedication to customer service, we’re one of the most trusted names when it comes to domestic hot water heat exchanger systems!

Contact Cooney Engineered Solutions For Your Domestic Heat Exchanger Needs Today

When you choose us as your go-to source for all things related to hot water heat exchangers, rest assured knowing that not only are you getting exceptional repair services but also full engineering consultation, design prototyping, and custom manufacturing processes too. Our team is always available should any questions arise regarding installation or maintenance needs concerning your particular setup! To reduce energy costs while gaining maximum efficiency with an ultra-efficient steam-to-hot water exchanger, contact us today!