Maximum Efficiency. Minimal Footprint.

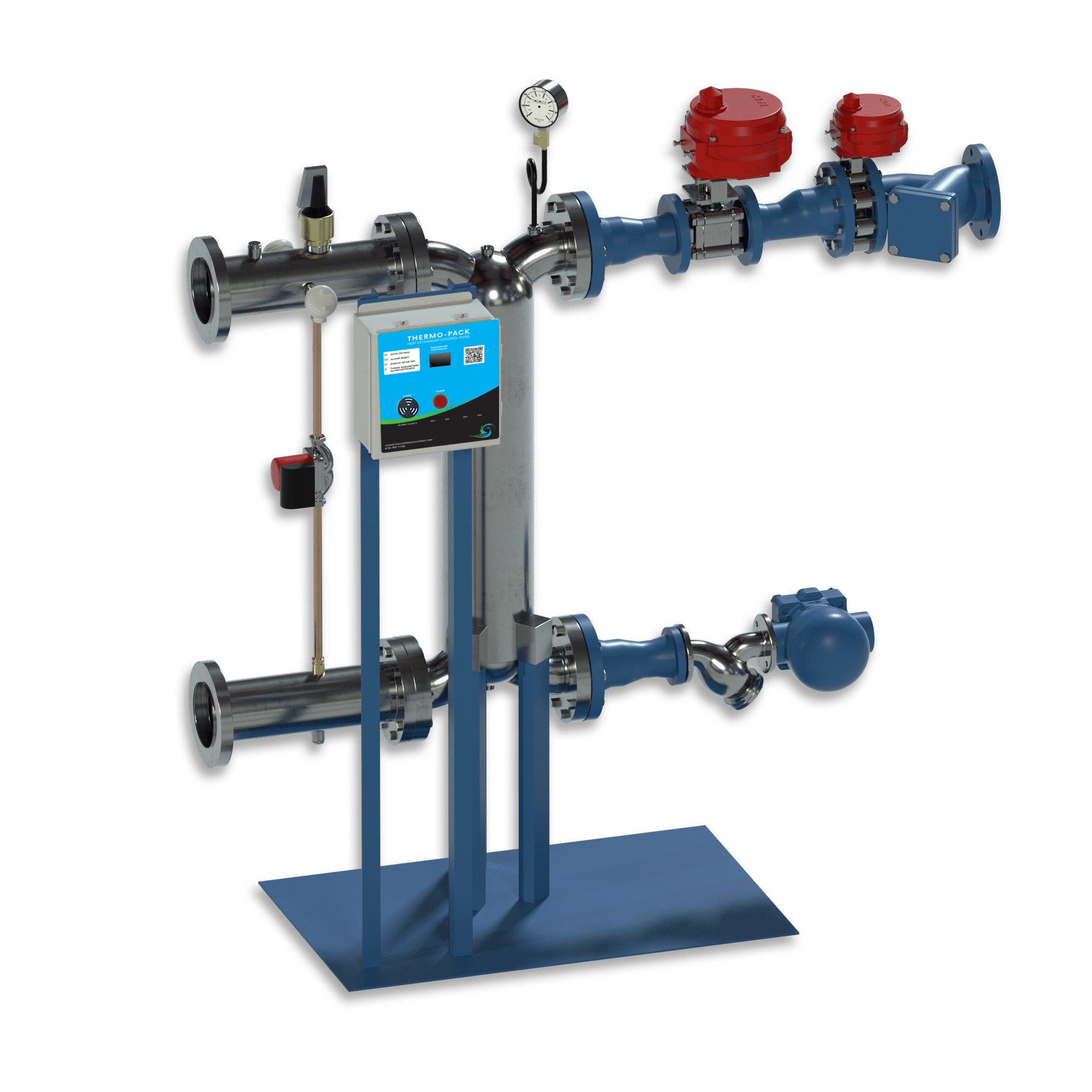

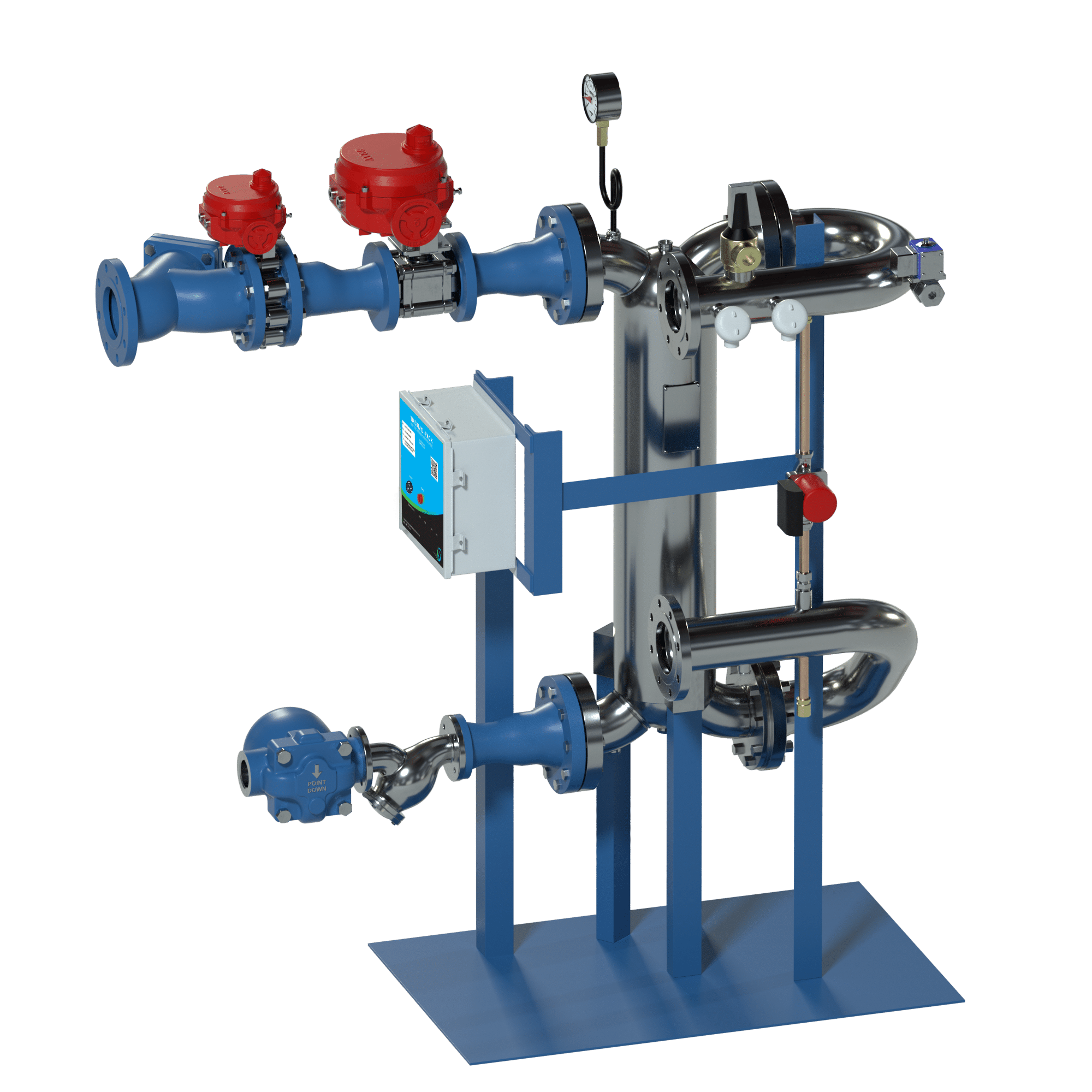

Thermo-Pack Heat Exchangers

Meet the Cooney Thermo-Pack Steam Heat Exchanger, your solution for efficient and reliable water heating. Available for domestic hot water, heating, and process applications.

Unlock Energy Savings

Eliminate Flash Steam Losses

Condensate Subcooling as low as 110° F

Unmatched Reliability

Why Choose Thermo-Pack?

Save Energy & Reduce Steam Consumption

Percisely Engineered for Tight Spaces

Durable Design, Minimal Upkeep

Versatile Solutions for Every Industry

From domestic hot water and heating to complex process applications, Thermo-Pack delivers unmatched performance. A trusted choice for facilities looking for efficeny and reliability.

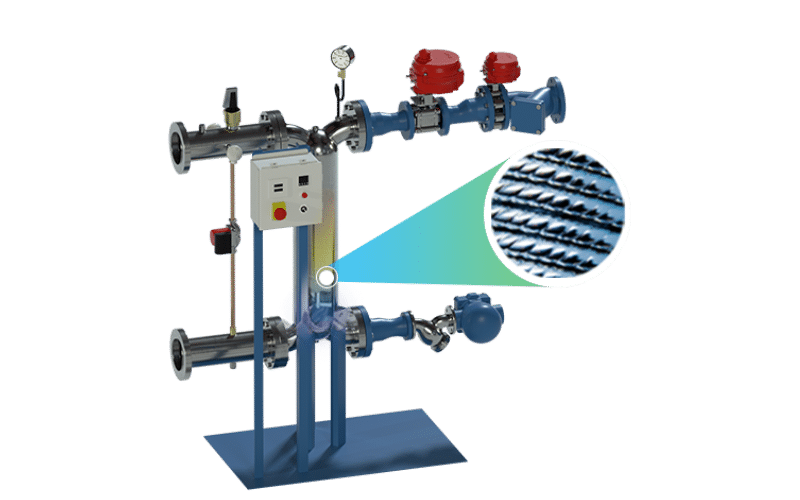

How Does it Work?

Capture Maximum Energy

Don’t let valuable energy go to waste. Thermo-Pack's advanced heat transfer technology ensures efficient energy recovery, lowering steam consumption and operating costs. Thermo-Pack optimizes performance, helping your facility get the most out of every pound of steam.

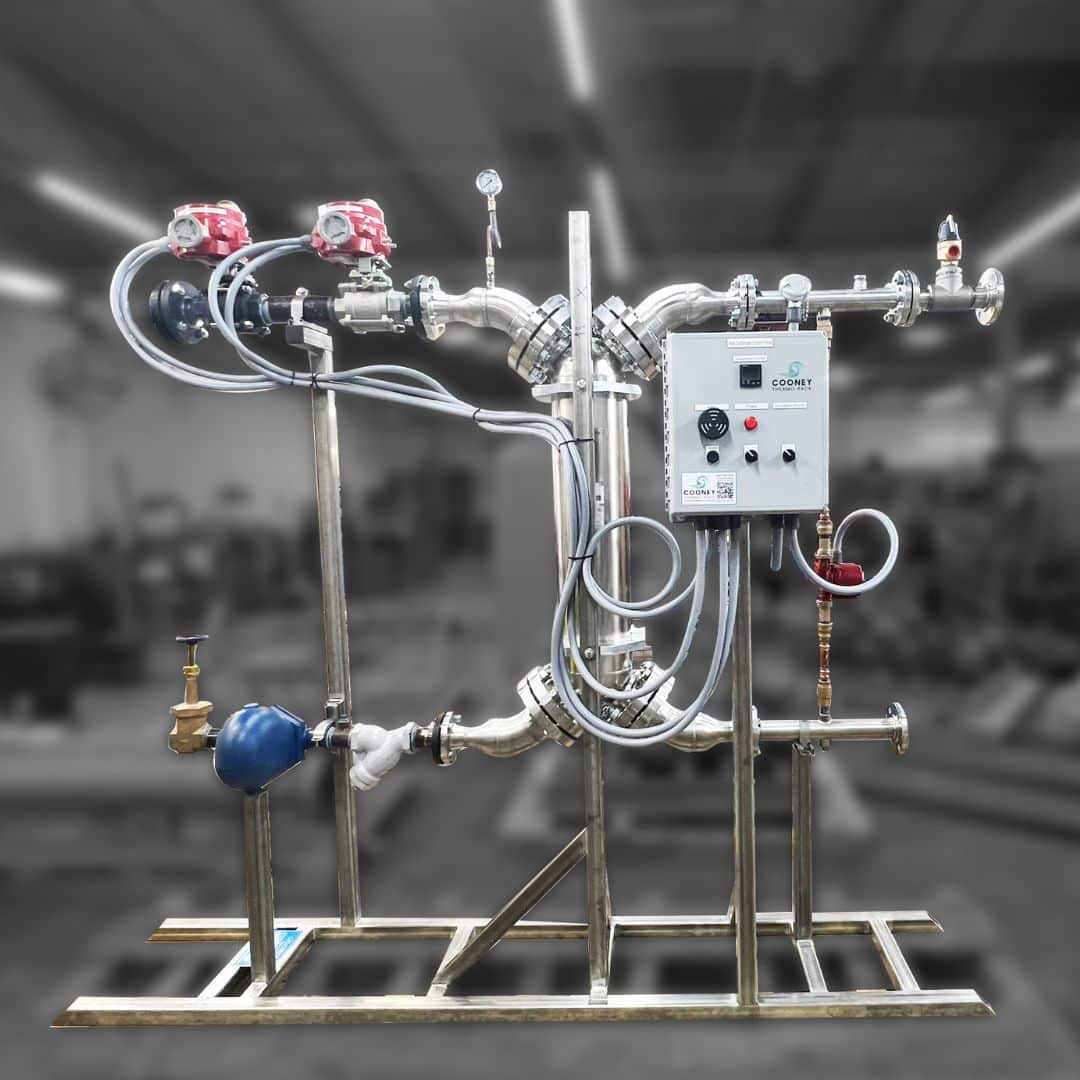

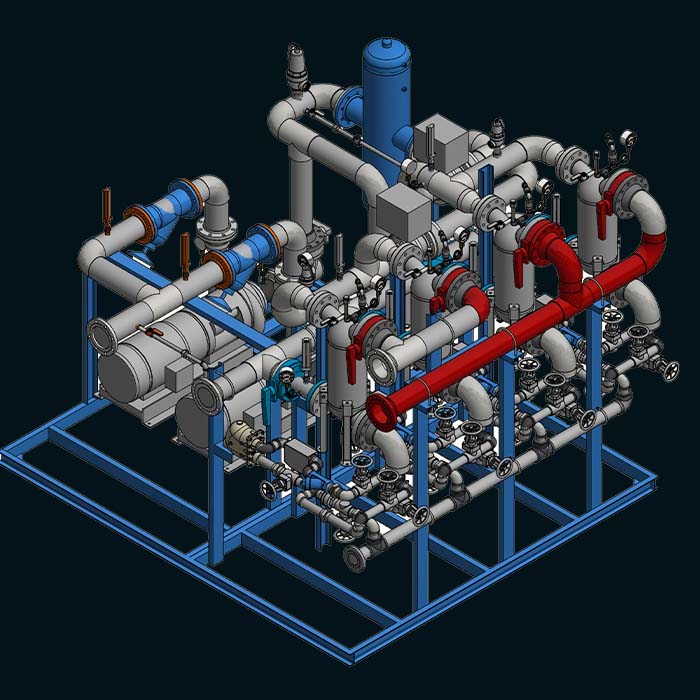

Easy Installation, Easy Operation

With flexible outlet orientations, a compact footprint, and plug-and-play skid assembly, the Thermo-Pack saves critical time and reduces installation costs.

Maintenance Made Simple

Constructed from durable SS 316L stainless steel, the Thermo-Pack resists wear and corrosion, keeping maintenance needs to a minimum. For easy upkeep, 3/4” threaded ports on the water side of the skis provide fast access for cleaning, ensuring smooth operation with minimal downtime.

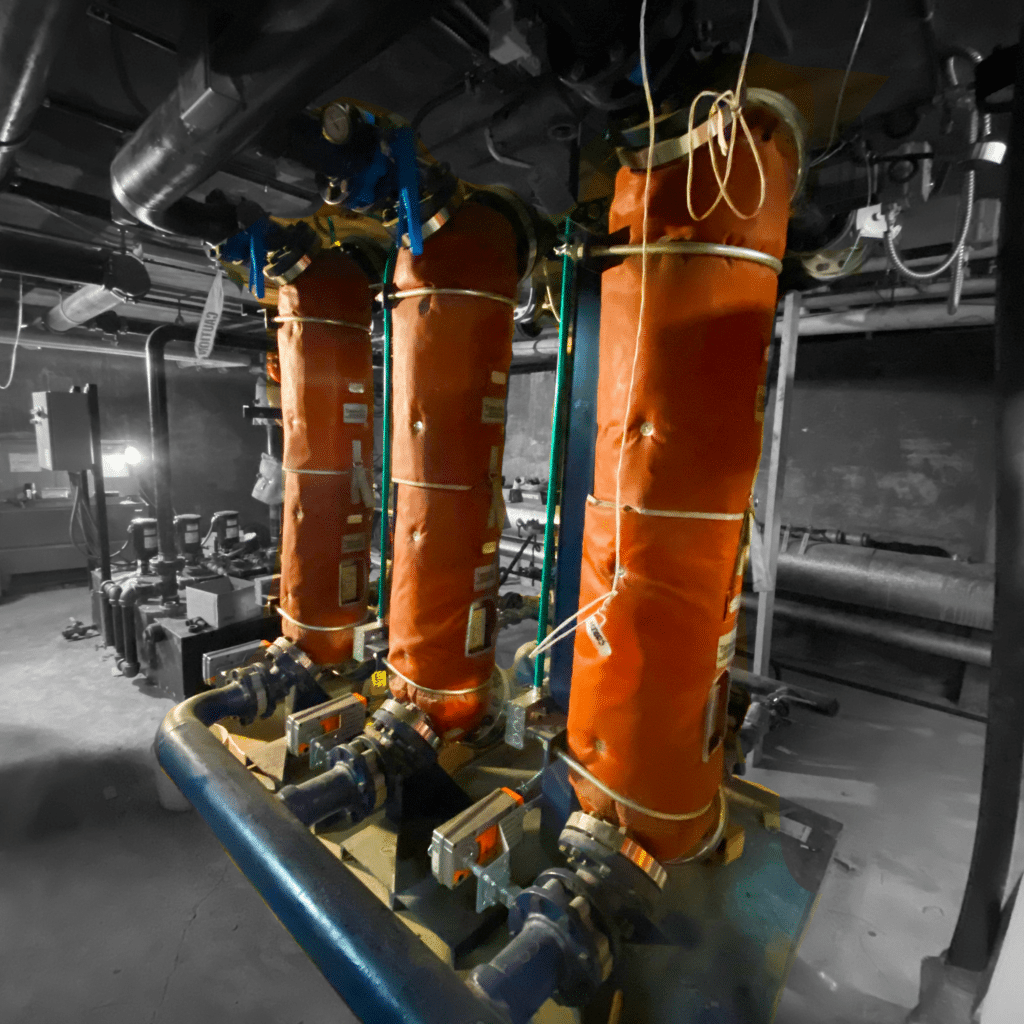

Industries & Applications

Thermo-Pack is a highly versatile steam-to-water heat exchanger for domestic hot water, heating, and process applications. Trusted across industries for its performance and reliability.

Facility managers value its durability and minimal upkeep, while energy managers appreciate its cost-saving efficiency. Thermo-Pack delivers.

Domestic Hot Water

Whether you’re running a dormitory, residential building, or any facility that requires a constant supply of hot water, the Cooney Thermo-Pack is the ideal solution. Its compact design and high heat transfer area efficiently convert steam into hot water with minimal energy loss. With optional components, you can tailor the Thermo-Pack to fit your specific hot water demand, ensuring a steady and reliable supply.

Heating Hot Water

Process Applications

What Our Customers Are Saying

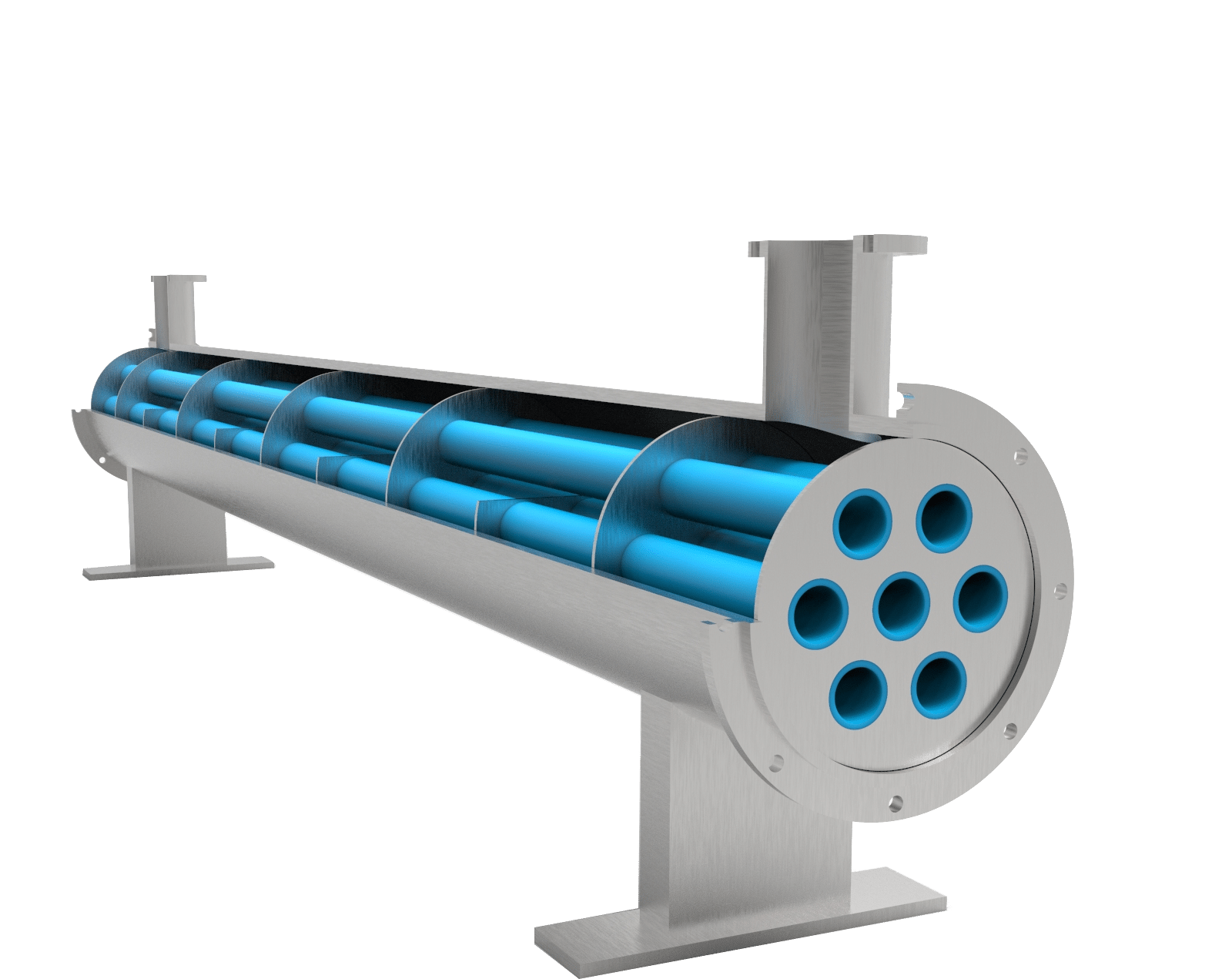

Thermo-Pack vs. Shell & Tube

Choosing the right heat exchanger can significantly impact your facility. The Thermo-Pack sets a new standard with superior energy savings, low maintenance demands, a compact design, and flexibility. Compare it side-by-side with traditional steam-to-water shell and tube models.

Discover how Thermo-Pack outperforms traditional heat exchangers. Contact us today to learn more and optimize your system!

Thermo-Pack

Captures latent & sensible heat, 10-15% energy savings.

Low upkeep, corrosion-resistant SS 316L.

High efficiency, scalable capacity.

Shell & Tube

No sub-cooling, less efficient.

High maintenance, prone to fouling.

Lower efficiency, less adaptable.

Steam Energy Savings

Maximize your energy efficiency and lower operational costs with the Thermo-Pack, the innovative heat exchanger designed to redefine performance. Its sub-cooling design enables you to save an impressive 10-15% on energy compared to traditional shell and tube heat exchangers. These savings not only reduce your energy use, but also help create a cleaner, more sustainable operation by minimizing your thermal footprint.

Want to see the numbers for yourself? Request a full energy analysis or calculate your ROI today and take control of your savings!