HVAC Coil Freeze Protection: Protecting Your Investment

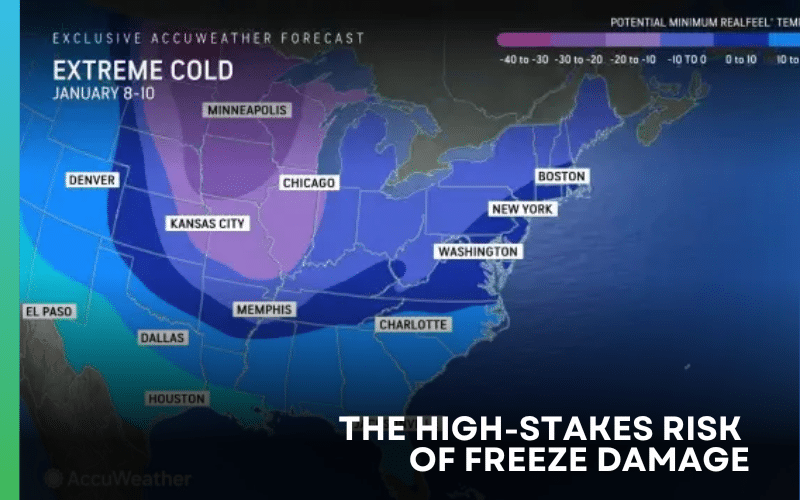

Fluid and steam HVAC coils are essential for maintaining a comfortable environment and they can suffer serious damage if exposed to freezing temperatures. Ruptured coils can cause a significant amount of damage. When the coil eventually thaws and tries to return to system pressure, flooding could occur—potentially leading to damaged equipment and mold and mildew remediation. If the coil needs to be repaired or replaced, this will cost both time and money. Facility downtime can result in lost revenue and productivity, as well as occupant dissatisfaction. Furthermore, if an insurance claim is filed due to the damage caused by a ruptured coil, premiums may increase going forward. All of these things combined make it important for facility managers and building owners to take steps to protect their HVAC coils against freezing temperatures.

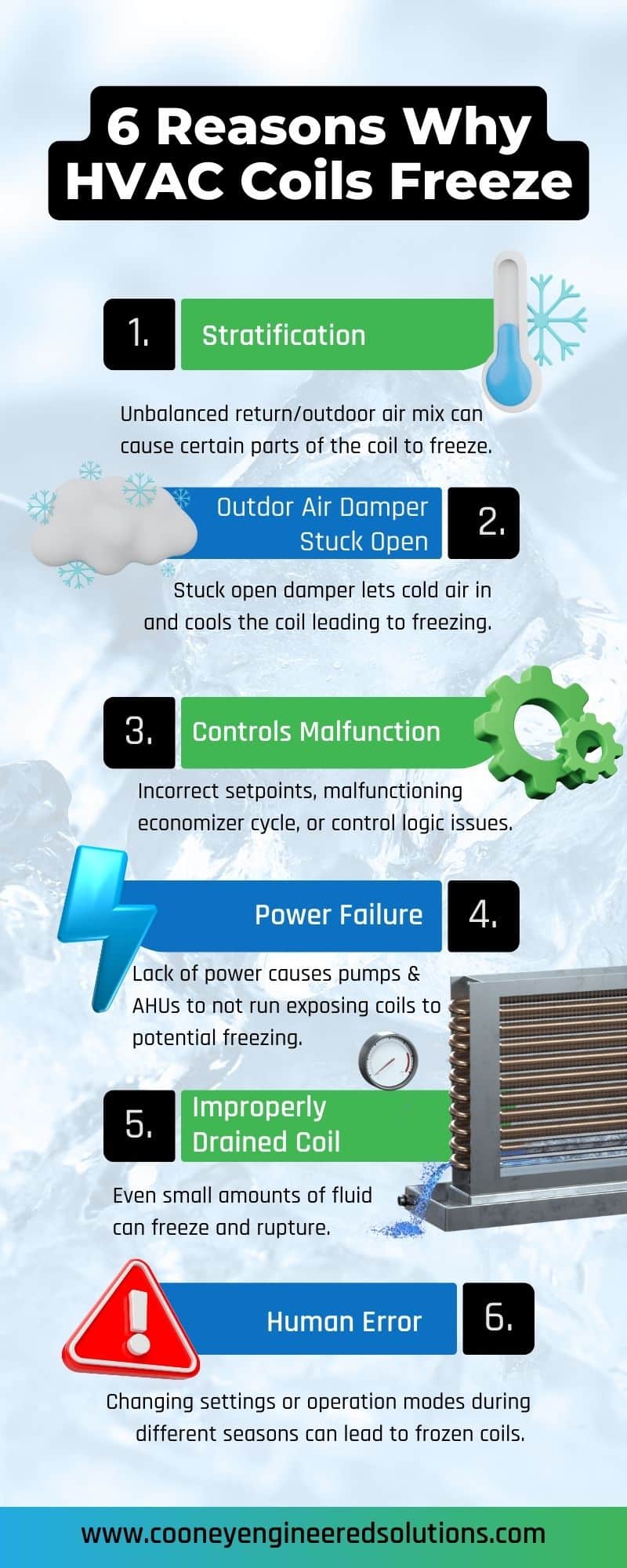

Reasons Why Coils Freeze

HVAC coils are prone to freezing due to several causes:

- Stratification – When the mix of return and outdoor air is not balanced correctly, stratification can occur, cooling certain parts of the coil more than others and potentially causing them to freeze.

- Outdoor Air Damper Stuck Open – If the outdoor air damper is stuck open, it can allow cold outside air to enter and cool the coil, leading to freezing.

- Controls Malfunction – Faulty controls or settings can cause coils to freeze. This could be due to an incorrect setpoint temperature, a malfunctioning economizer cycle, or an issue with the system’s control logic.

- Power Failure – If the power to a building or facility fails, the circulating pumps and AHUs will not run and coils will be exposed to cold air, leading to freezing.

- Improperly Drained Coil – Even a small amount of fluid left in a coil has the potential to freeze and create enough pressure to rupture an HVAC coil’s return bends.

- Human Error – changing settings or operation modes that were intended for one season but have unintended consequences during another season can lead to frozen coils.

By incorporating the appropriate strategies and one or more coil freeze protection technologies, you can prevent frozen HVAC coils.

Coil Freeze Protection Technologies

Freeze Stats

Freeze stats are a low-temperature limit control device used to protect hot or chilled water coils in an air handler and can be effective in preventing freezing. However, nuisance alarms caused by the freeze stat are common and may result in maintenance departments lowering the trip temperature. It’s important that the freeze stat trips before the coil freezes to avoid ruptured coils. To ensure proper operation of the freeze stat, calibrations and trip tests should be done annually before cold weather arrives. Following the sequence of operation when testing is also important to prevent costly repairs from frozen coils.

Draining Coils During the Winter

Draining fluid HVAC coils during the winter is a preventative measure to avoid frozen or ruptured coils. It can be difficult to determine the best time for draining when dealing with unpredictable temperature swings and warm weather extending into fall. Facilities departments are also challenged with a shortage of labor. Often we see preventative maintenance suffer as a result. To ensure this process is done correctly, it should be given plenty of attention and adequate manpower should be allocated for doing so before cold weather begins.

Recirculating Pump

Recirculating pumps are another option to prevent the freezing of fluid HVAC coils. These pumps keep water moving throughout the coil, ensuring that it is above freezing temperature even when outdoor temperatures drop. Regularly scheduled maintenance and inspections should be done for any recirculating pump system in order to ensure proper operation before cold weather arrives. If the power to a recirculating pump system fails, the water will eventually cool and freeze within the coil. If this occurs, it can lead to ruptured coils, damaging equipment and requiring costly repairs or replacements.

Recirculating pumps are another option to prevent the freezing of fluid HVAC coils. These pumps keep water moving throughout the coil, ensuring that it is above freezing temperature even when outdoor temperatures drop. Regularly scheduled maintenance and inspections should be done for any recirculating pump system in order to ensure proper operation before cold weather arrives. If the power to a recirculating pump system fails, the water will eventually cool and freeze within the coil. If this occurs, it can lead to ruptured coils, damaging equipment and requiring costly repairs or replacements.

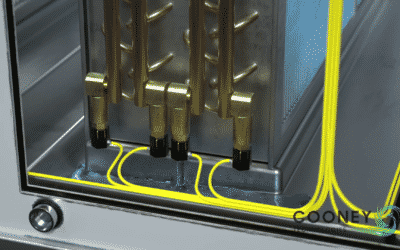

Freeze Block Technology

Freeze Block technology can be applied to both steam hot water or chilled water coils as an additional layer of protection alongside other freeze prevention strategies.

Freeze Block Coils protect against freeze damage and prevent bursting by incorporating a pressure and temperature relief valve integrated with an expansion relief header. When freezing conditions occur, the Freeze Block valve will sense this and release a controlled amount of fluid from the coil, allowing ice to form without rupturing it. The valve is also designed to reseat, allowing the coil to return to normal operation once thawed. This technology is the only one of it’s kind and has saved countless coils from bursting.

The Freeze Block Coil is a great way to protect against freezing and potential damage from bursting coils. It offers freeze protection that doesn’t rely on power, so it won’t be affected if there’s an outage. It can also be used with water for increased efficiency without the use of glycol, so it’s a more environmentally friendly option. Plus, there are no nuisance alarms and little to no maintenance required. All of these features make the Freeze Block coil an ideal choice for facilities looking to protect their HVAC system from freeze damage.

Glycol

Glycol is an antifreeze solution of ethylene or propylene glycol mixed with water that can be circulated through an open or closed system. The glycol prevents the coil from freezing by lowering the freezing point of the fluid. Using glycol in an HVAC system can be effective in preventing coils from freezing, however, there are some considerations. The concentration of glycol must be carefully monitored and adjusted regularly to keep the freeze point low enough to prevent freeze-ups. Also, as the concentration of glycol increases, so does energy consumption – resulting in higher costs for running the system. Finally, glycol may eventually need to be replaced due to evaporative losses or contamination from other materials that can decrease its effectiveness over time. Overall, using glycol is a viable solution for coil protection but careful maintenance and monitoring are necessary to ensure it’s working properly and efficiently.

Don’t Let Your HVAC Coils Freeze this Winter

HVAC coils can freeze due to a variety of factors including control issues, power failure, and even human error. The good news is that there are a variety of strategies and technologies available for protecting your HVAC coils from freezing, such as glycol, freeze stats, draining coils during winter months, and Freeze Block Coils. To learn more about which strategy is right for your facility, we invite you to reach out and set up a lunch & learn with our team. We can provide more detailed information about the options available and help you determine which strategy will best fit your needs. Let us help protect your HVAC system from freezing!

Don't let your HVAC coils freeze this winter - take action now and protect them with Freeze Block Coils!

Freeze Block Coils are designed to prevent bursting of frozen coils by incorporating a pressure and temperature relief valve, combined with an expansion relief header. This specialized technology provides reliable protection against freezing without relying on power, and requires little to no maintenance. Plus, it’s more environmentally friendly than other antifreeze solutions. Protect your HVAC system today and invest in Freeze Block Coils – the perfect solution for freeze protection!