Enhancing HVAC efficiency is a hot topic for facility managers and building owners looking to lower energy usage and reduce their carbon footprint. HVAC coils play a major role in system performance, and by implementing specific upgrade strategies, you can boost efficiency.

Aging Infrastructure & The Need for Efficient Replacement Coil Options

The buildings in North America, including schools (average age: 42 years) and commercial buildings in the US (average age: 53 years), are getting older, highlighting the widespread need for proactive maintenance and upgrades. The lack of OEM replacement coils and parts for HVAC systems further complicates maintenance.

Thankfully, at Cooney Engineered Solutions, we manufacture custom replacement coils tailored to fit existing air handling units (AHUs). This, combined with the ability to optimize coil performance, presents an opportunity to:

- Improve System Efficiency

- Reduce Energy Costs

- Ensure Performance

Partnering with experts in heat transfer technology and coil freeze protection can maximize the potential of HVAC systems, contributing to sustainable and resilient built environments.

Understanding HVAC Coil Performance

To effectively strategize HVAC coil retrofit upgrades, it’s critical to understand the various types of HVAC coils and the factors that influence their performance.

Coil Types

HVAC coils come in a variety of designs tailored to specific functions, from heating air to condensing refrigerant. Each type has unique performance characteristics and requirements.

Fluid Coils

-

- Supply connections typically at the bottom of the coil

- Visible return bends

- Normally has vent and drain connections

Standard Steam Coils

-

- Supply and return headers

- Supply connection typically in the middle of the supply header

- Condensate drain located at the low point of the coil

- Rows limited to 4 and connected by return bends

- Same or opposite end connection construction

Steam Distributing Coils

-

- Supply connections in the middle of the header with no return bends

- Rows limited to 2 rows with 5/8” or 1” tube construction

Direct Expansion (DX) Coils

-

- Distributor leads (spaghetti tubes) and expansion valves

- Can have multiple distributor arrangements

Condenser Coils

-

- Supply connection enters at the top of the coil

- Similar appearance to water coils, except for the location of the supply connection

- Sub-cooler circuits typically have separate headers and represent a small portion of the coil’s surface.

Performance Factors

There are many factors that go into determining the performance and efficiency of a coil. Working with our knowledgeable coil selection experts when ordering energy efficient replacement coils can help you to get the best coil performance for your application.

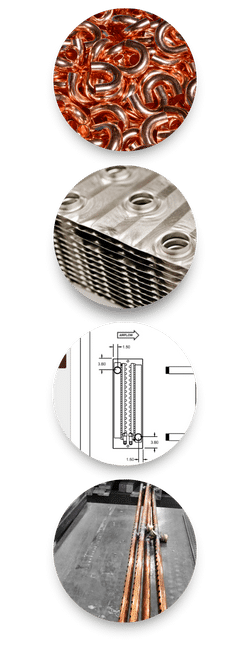

- Construction Materials: The materials used in coil construction, such as stainless steel or cupro-nickel, can impact durability and heat transfer properties.

- Fins and Tubes: These components play a critical role in increasing the surface area for heat transfer, with different materials and configurations catering to various environmental conditions and applications.

- Circuiting: The arrangement of tubes and how they pass through a coil greatly affects overall performance. Optimal circuiting can maximize heat transfer while minimizing air resistance, leading to improved efficiency.

- Coil Sizing: Proper sizing ensures optimal performance, as undersized coils can result in insufficient heat transfer and oversized coils can lead to excess energy consumption.

Other Recommendations

- Space Optimization: Enlarging coil sections when space allows reduces velocity, leading to energy savings over the unit’s life.

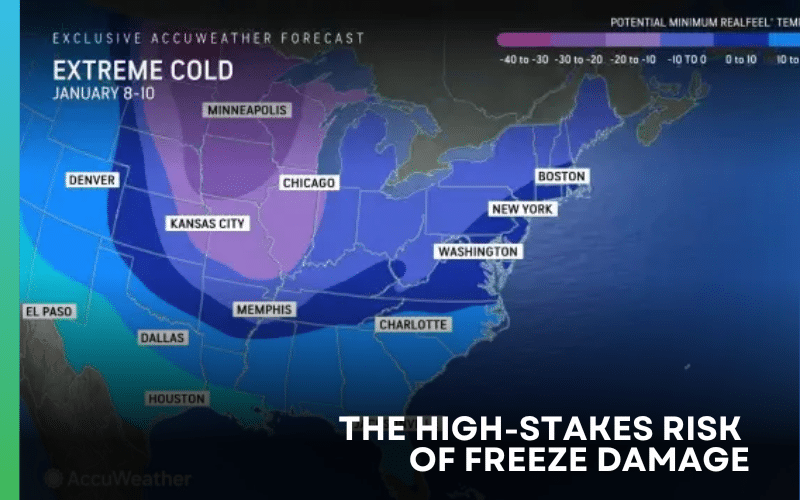

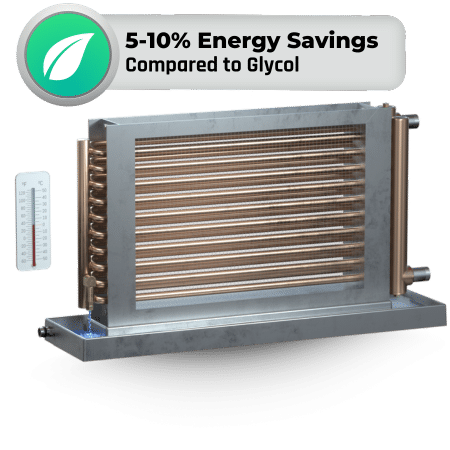

Glycol Usage: Glycol (antifreeze) negatively affects heat transfer properties, which requires more rows of tubes to get the same job done that water. Glycol increases the fluid pressure drop as well; the higher the concentration of glycol the worse performance and pressure drop. Consider Freeze Block coils as an energy-saving alternative to glycol for burst protection and coil freeze protection.

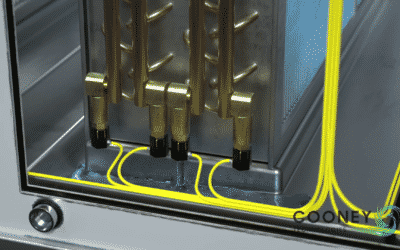

Glycol Usage: Glycol (antifreeze) negatively affects heat transfer properties, which requires more rows of tubes to get the same job done that water. Glycol increases the fluid pressure drop as well; the higher the concentration of glycol the worse performance and pressure drop. Consider Freeze Block coils as an energy-saving alternative to glycol for burst protection and coil freeze protection.- Smart Investments: The cheapest replacement coil isn’t always the best long-term option. Upgrading materials to enhance performance and reliability can lead to longer equipment lifespan and reduced energy consumption. For instance, incorporating Freeze Block technology in HVAC coils can prevent bursts or ruptures, ultimately saving on future replacements due to freeze damage and minimizing downtime.

Conclusion: The Benefits of Efficient Coil Upgrades

Upgrading your building’s coils is a strategic decision with great implications for your bottom line and environmental footprint.

Upgraded Efficiency

With the help of coil selection experts, coils can be engineered to improve heat transfer efficiency. These upgrades can often pay for themselves through energy savings within a few years.

Extended System Life

By reducing strain on HVAC systems, upgraded coils can prolong the working life of the entire unit. This translates to delayed replacement and lower lifetime cost of ownership.

Environmental Footprint

Energy savings also translate to a direct reduction in greenhouse gas emissions. Coil upgrades

align with green initiatives, offering a clear path towards a more sustainable operation.

With an aging building infrastructure and increased focus on sustainability goals, it’s more important than ever to prioritize efficiency. With expert guidance and innovative products like our Freeze Block technology, Cooney Engineered Solutions is here to help you take your building’s sustainability and performance to the next level. Let us partner with you on your next coil replacement or retrofit project – contact us to get started.