How Do HVAC Coils Freeze?

Frozen coils can wreak havoc on your HVAC system and building. It’s not just about repair costs – it’s about keeping your operations running smoothly.

How HVAC Coils Freeze

Coils can freeze in any HVAC system, including hot water, chilled water, glycol, and steam coils. But how does this happen?

Understanding Why HVAC Coils Freeze

Let’s dive into the causes of coil freeze and how you can prevent it.

Preventing Freeze Damaged Coils

We’ll outline measures to keep your HVAC system humming along, free from the icy grip of coil freeze.

How Do Fluid & Steam Coils Freeze?

What are Fluid HVAC Coils?

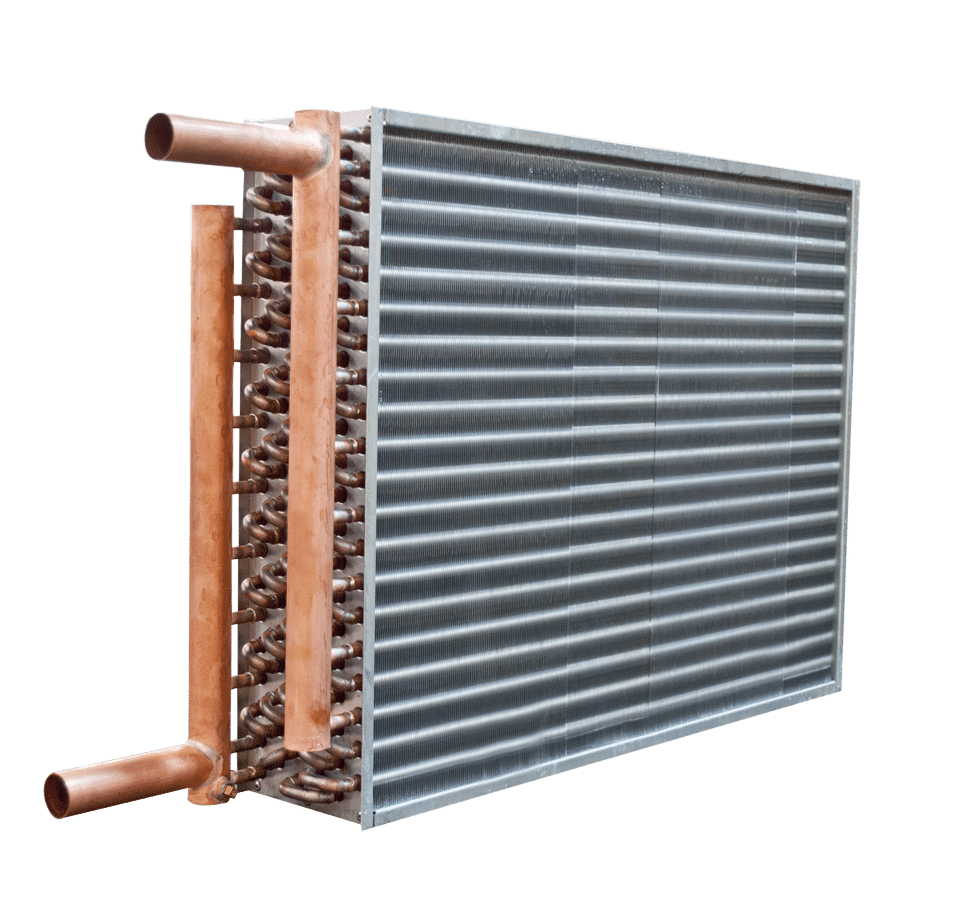

Fluid coils are a type of heat exchanger that can be used for both heating and cooling. They work by transferring heat from the water flowing through the coil to the air passing over it. Types of fluid coils include hot water coils, chilled water coils, and glycol coils.

How do Fluid Coils freeze?

At temperatures 32°F and below, water can freeze and expand, causing excessive pressures that result in coil damage within a matter of minutes. The ice that forms within the tubes of a hot water or chilled water coil expands and builds immense pressure causing a split that leaks fluid everywhere once thawed.

Water-damaged floors, walls, and equipment, mold and mildew remediation can all be the result of just one ruptured tube. And we often see multiple splits throughout a ruptured coil.

Stratification

Understanding the mechanics of coil freezing in HVAC systems is essential for maintaining an efficient and functional heating, ventilation, and air conditioning system. One of the causes behind this phenomenon is stratification.

Stratification refers to the uneven distribution of temperature within the airstream entering a coil. Contrary to popular belief, the airstream is not usually isothermal or at the same temperature throughout its entirety. This disparity in temperature, coupled with the stark difference in air densities between outdoor air and return air, results in stratification.

The entire airstream does not need to be at 32°F to freeze a coil. If a select portion of a coil is consistently exposed to low temperatures, that portion of the coil can freeze and rupture while the remainder of the coil is exposed to standard mixed air temperatures.

What are Steam HVAC Coils?

A steam coil is a heat exchanger often found in the air handling units of commercial and industrial buildings. It works by warming up air that fans blow across fins made of materials like aluminum, copper, or stainless steel. These fins get heated up from steam moving through tubes.

A steam coil is a heat exchanger often found in the air handling units of commercial and industrial buildings. It works by warming up air that fans blow across fins made of materials like aluminum, copper, or stainless steel. These fins get heated up from steam moving through tubes.

There are two kinds of steam coils: standard and steam distributing. Standard steam coils are usually used for reheating, while steam distributing coils are needed when the air coming in is below 40 F degrees.

How do Steam Coils freeze?

A problem that can happen with steam coils called a freeze-up. This is when the leftover water, or condensate, inside the steam coil tubes freezes. The two main causes of this are issues with the steam trap and the vacuum breaker.

The steam trap’s job is to get rid of the condensate once it forms, usually in the lowest part of the coil. If the steam trap isn’t installed right, the condensate will stay in the coil and freeze when it comes into contact with outside air.

The vacuum breaker also helps remove the condensate. Plus, it prevents water hammers (loud banging noises caused by steam flow) and helps even out temperatures. It needs to be installed on the control valve and always above the steam trap.

Why Do Fluid & Steam Coils Freeze?

Fluid HVAC coils, including hot water, chilled water, and glycol coils, are particularly susceptible to freezing. Common reasons for coil freeze-ups are central plant or power failure, mechanical malfunction, human error, or improperly drained coils.

Central Plant or Power Failure

When a big power outage happens, it can cause the pumps and Air Handling Units (AHUs) to stop working. The AHUs help control the temperature in your building. Without power, the inside of the AHU cabinet will become as cold as it is outside.

This is a big problem, especially in the winter. When it gets too cold, the coils can freeze and burst. In fact, they can be one of the first things in the building to freeze.

In a steam or hot water plant, different problems can occur that stop the plant from heating a coil as expected.

These problems can even cause the coils to freeze, which disrupts the entire system. Some of these issues include:

-

Pressure Regulator Valve (PRV) Failure: Think of this like a gatekeeper that controls how much hot water or steam flows into the coil. If it fails, it can cause the coil to freeze.

-

Control Valve Failure: Control valves also help manage the flow of steam or hot water. A problem with this valve can also cause a coil to freeze.

-

Blockage in Piping: This is like a traffic jam in your heating system. If there’s a blockage, the hot water or steam can’t reach the coil.

-

Central Boiler Failure: The boiler is like the heart of your heating system. If it stops working, it can cause everything else – including your coils – to freeze.

Mechanical Controls Failure

Mechanical malfunctions, such as broken fans or damper failure can hinder airflow, causing the coils to freeze.

OA dampers are frequently designed for economizer mode to allow 100% OA during swing seasons. However, damper and springs rust, actuator failure, and control failures can prevent the dampers from closing during winter or during the startup/shutdown of the unit.

Obstruction is another common factor contributing to damper failure. Obstruction can be caused by something as minor as dust buildup or as significant as a mechanical issue like binding, something bent, or an object jammed in the damper blades.

When dampers fail, it can result in unexpected freezing conditions occurring at a coil, leading to the rupturing of the coil.

Human Error

Sometimes, service technicians and building maintenance workers have to adjust equipment setpoints. They might do this to fix a problem that happens in one season, but this can cause other problems in a different season.

Sometimes, service technicians and building maintenance workers have to adjust equipment setpoints. They might do this to fix a problem that happens in one season, but this can cause other problems in a different season.

For example, they might change a setting on an outdoor air louver to let in more outside air during a mild season. This takes advantage of the nice weather to keep the building comfortable. But if they forget to change the setting back when the weather gets too hot or too cold, it can cause problems.

This is because letting in too much outside air during extreme weather can be hard on the coil, another part of the system. It can even cause the coil to freeze unexpectedly. This could happen even if the coil was designed to handle only a small amount of outside air.

So it’s important to remember to inspect the settings on your equipment as the seasons change. This will help prevent unexpected problems like a frozen coil. Our product can also help protect your coils from freezing, even under tough conditions.

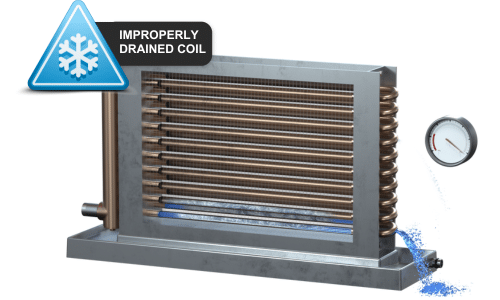

Improperly Drained Coils

Proper draining of the coils is essential to prevent freezing. If coils are not properly drained, even a small amount of residual water can pose a significant risk.

When the temperature drops below freezing, this leftover water can turn into ice. As the water freezes and expands, it creates pressure within the coil’s tubing. This pressure buildup can be substantial enough to cause the tubes to rupture or burst.

How to Prevent Freeze Damage HVAC Coils

Preventing coil freezing and rupture can involve a combination of various strategies, including Freeze Block Coils, the use of freeze stats, periodic draining of coils, recirculating pumps, or using glycol for antifreeze, each with its own set of considerations and maintenance requirements.

Freeze Block Coils

Freeze Block technology offers additional protection for both steam hot water or chilled water coils. It incorporates a pressure and temperature relief valve integrated with an expansion relief header. In freezing conditions, the Freeze Block valve releases a controlled amount of fluid from the coil, allowing ice to form without rupturing the coil. The valve reseats and once the coil is thawed it returns to normal operation. This technology has saved numerous coils from bursting. It is a power-independent, environmentally friendly freeze protection solution with minimal maintenance requirements.

Freeze Stats

Freeze stats are devices that monitor low-temperature limits. They primarily used to safeguard hot or chilled water coils in an air handler. They can be a useful tool in preventing freezing, but they also have a propensity for nuisance alarms. This often leads maintenance departments to lower the trip temperature. To prevent coil rupture, it is crucial that the freeze stat trips before the coil freezes. Annual calibrations and trip tests before the onset of cold weather are necessary to ensure the proper functioning of the freeze stat.

Draining Coils During the Winter

Draining HVAC coils in the winter is a preventive measure facilities can take against coil freezing or rupturing. The challenge lies in predicting the best time for draining due to fluctuating temperatures and extended warm weather into the fall season. The process requires adequate manpower and attention, especially considering labor shortages in facilities departments.

Recirculating Pumps

Recirculating pumps keep water moving in the coil, maintaining a temperature above freezing even when the outdoor temperature drops. Regular maintenance and inspection of these pump systems are essential to ensure their proper operation before cold weather sets in. Power failure can cause the water within the coil to cool and freeze, leading to coil bursts or rupture.

Glycol

Glycol, an antifreeze solution mixed with water, can be circulated through HVAC systems to prevent coil freezing by lowering the fluid’s freezing point. Careful monitoring and regular adjustment of the glycol concentration are required to maintain a low freeze point. Increased glycol concentration leads to higher energy consumption and operational costs. Over time, the effectiveness of glycol may decrease due to evaporative losses or contamination.

In areas with extremely low temperatures, glycol remains a viable solution for coil protection with proper maintenance and monitoring although operating and maintaining it can be very costly.