For centuries, steam energy has powered the engines and machines that have driven our progress. Steam is the lifeblood of numerous industrial sectors, it remains a critical resource, even in today’s energy-conscious world, where maximizing efficiency without compromising on output is an ongoing optimization challenge.

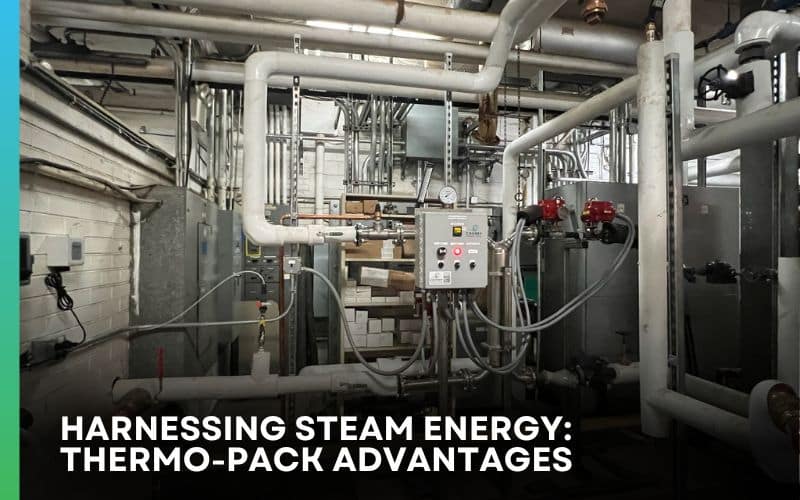

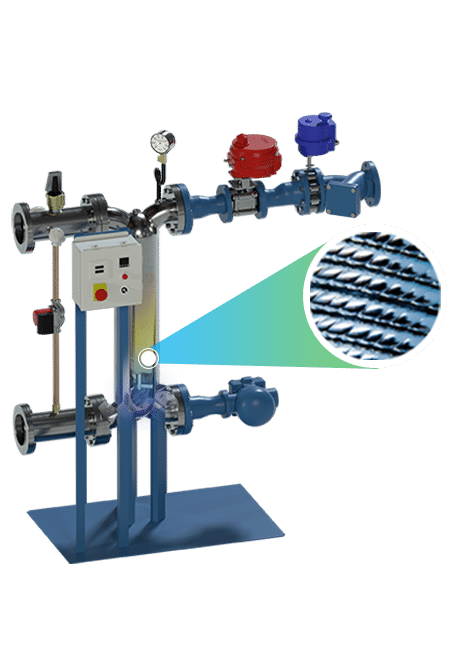

Understanding the need to improve energy efficiency, Cooney Engineered Solutions has created the Thermo-Pack. Unlike shell and tube heat exchangers or immersion bundles, Thermo-Pack steam-to-water heat exchangers are compact skid systems designed to save your campus energy and reduce maintenance. Using cutting-edge shell & coil heat exchanger technology, this device provides efficient and reliable water heating for domestic hot water, building heat, and process applications.

Advanced Heat Exchanger Design

The shell and coil heat exchangers used in the Thermo-Pack maximize efficiency in limited spaces while ensuring durability and reliable operation. These heat exchangers are suitable for a wide range of industrial and district energy applications where space and performance available for heat transfer are paramount.

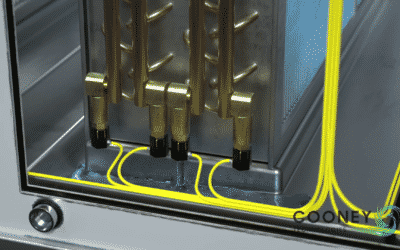

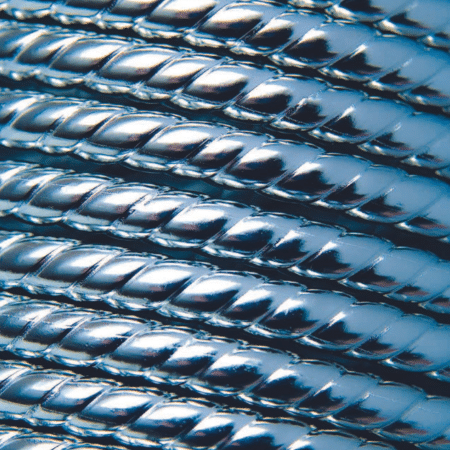

Increased Heat Transfer Surface Area

The criss-cross pattern formed by alternating the direction of each layer significantly enhances the available surface area for heat exchange within a limited volume. This means that despite its compact size, the JAD heat exchanger does not compromise on its heat transfer capabilities.

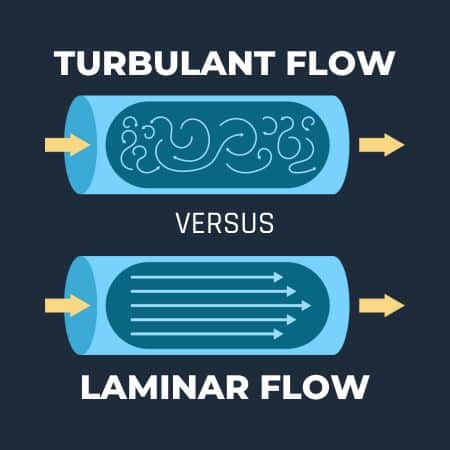

Enhanced Fluid Dynamics

The tubes orientation encourages turbulent flow. Turbulent flow as opposed to laminar flow, greatly increases the mixing of the fluids. This results in more uniform heating or cooling, which, in turn, improves the efficiency of heat transfer. The overall heat transfer coefficient, a measure of the heat transfer capability of the heat exchanger, is therefore higher.

Durability

The environment for industrial steam heat exchangers can be harsh, characterized by high temperature differentials, varying steam pressures, and the potential for hammer and shocks. The helically corrugated tubes spring-like characteristics and stainless-steel construction, offer resilience against these stresses. This not only ensures reliable operation and extends the lifespan over traditional heat exchanger options.

Maximizing Steam Energy Efficiency

Engineered for optimal performance, Thermo-Pack gains efficiency by sub-cooling steam condensate. This process utilizes the maximum amount of energy from every pound of steam to boost efficiency and eliminate flash steam, helping facilities save energy and extend equipment life.

To understand the energy-saving potential of the Cooney Thermo-Pack, we invite you to explore our steam energy comparison tool. This innovative calculator allows you to directly compare the energy savings achievable with the Thermo-Pack versus traditional shell and tube heat exchangers.

Steam Energy Comparison

Ready to revolutionize your energy usage and significantly cut costs? On average, users enjoy a remarkable 10-15% energy savings compared to traditional shell & tube heat exchangers. Dive into our energy analysis tools and calculate annual energy savings today!

Minimizing Maintenance

A key advantage of the Thermo-Pack steam-to-water heat exchanger lies in its ability to lower condensate temperatures. This reduction plays a crucial role in diminishing the thermal stress and subsequent maintenance demands on condensate pumps and other vital components of the steam system. Lower temperatures mean less thermal expansion and contraction of equipment, leading to extended life and fewer breakdowns.

A key advantage of the Thermo-Pack steam-to-water heat exchanger lies in its ability to lower condensate temperatures. This reduction plays a crucial role in diminishing the thermal stress and subsequent maintenance demands on condensate pumps and other vital components of the steam system. Lower temperatures mean less thermal expansion and contraction of equipment, leading to extended life and fewer breakdowns.

The complete SS 316L welded construction of the heat exchanger ensures strength, durability, and longevity. Stainless steel 316L offers unparalleled corrosion resistance from the tube to the tube sheet and shell.

Engineered with smart design choices, the Thermo-Pack doesn’t require a lot of upkeep, saving you time and money. Its robust construction and corrosion-resistant materials can hold up to harsh industrial environments.

Compact Design & Custom Options

The Cooney Thermo-Pack’s compact vertical design allows the packaged heat exchanger to easily fit into tight mechanical rooms, with customizable dimensions and connection orientations that help reduce installation time and costs.

Understanding that every project has its unique challenges and requirements, we at Cooney Engineered Solutions pride ourselves on our ability to offer customized solutions that meet your exact needs. Tailoring the Thermo-Pack heat exchanger is not just an option; it’s a part of our customer-centric approach. Whether it’s adapting dimensions to fit your available space or altering connection orientations to streamline installation, our team is committed to engineering a solution that aligns with your project’s specific needs.

Innovative thinking extends to our standard units as well. Recognizing the importance of solutions for more time-sensitive projects, we offer a selection of pre-engineered Thermo-Packs. These units are a commitment to efficiency and quality, ensuring that even off-the-shelf solutions meet the high standards expected of Cooney products.

Improve Your Steam Efficiency Today with Cooney Thermo-Pack Heat Exchangers

Every Thermo-Pack is built with a focus on maximizing your system’s efficiency and reliability.

Our commitment to sustainable, efficient, and reliable energy solutions drives us to support facilities in various industries, from education to healthcare to manufacturing. Contact us today to start your journey towards a more energy-efficient future with Cooney Thermo-Pack.