Steam systems have been widely used in commercial and educational buildings for decades. Many existing buildings still rely on old steam to water heat exchangers for domestic and heating hot water. Traditional heat exchangers often may require renovation or troubleshooting, due to maintenance and reliability issues. In this blog, we’ll explore steam heat exchangers, specifically the shell and coil type and their benefits.

An Overview of Popular Heat Exchanger Types

There are several types of steam to water heat exchangers, each with its unique strengths. Among them, hot water generator storage tanks, the shell and tube, plate and frame, and shell and coil stand out for their efficiency and versatility.

Hot Water Generator Storage Tank

Hot water generator/storage tanks have been facilitating domestic hot water generation in facilities for years. They employ either a steam immersion bundle or a 180°F heating hot water bundle in a large storage tank. Despite their popularity, these tanks come with drawbacks such as a large footprint, reduced energy efficiency, potential Legionella concerns, and maintenance issues when leaks occur.

Plate and Frame Heat Exchanger

Plate and frame heat exchangers are prevalent in industrial applications. They consist of several metal plates with gaskets between each plate to create separate channels for fluid flow. However, they may present problems with high-temperature steam applications due to gasket wear and tear and may clog if used with improperly filtered water. Generally these are better suited to water-to-water applications.

Shell & Tube Heat Exchanger

Shell and tube heat exchangers are very common type of heat exchanger used in commercial and industrial settings. These consist of a tube bundle within an outer shell. While they offer good temperature control and can handle large volumes of fluids, their large footprint can make maintenance difficult, and they may present issues with pull space for bundle replacement and flash steam in the condensate system.

Shell and Coil Heat Exchanger

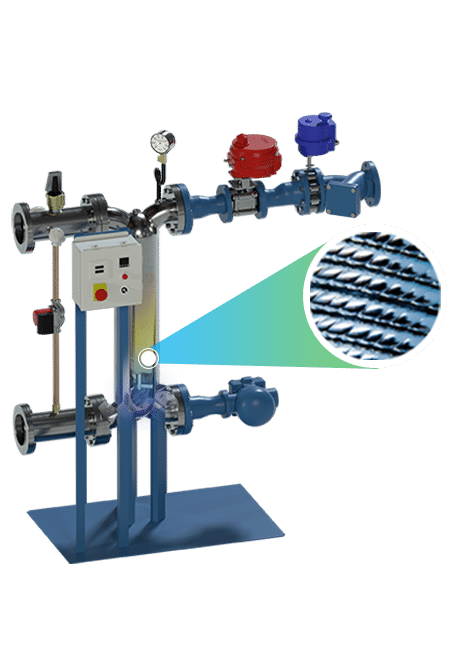

At the heart of these heat exchangers, you’ll find a compact, vertical design that houses a substantial heat transfer surface area. This setup allows for optimized use of space, making it an excellent choice for facilities with tight mechanical rooms.

But how does it achieve this superior performance? The answer lies in its use of cross-counterflow sub-cooling. This technology enables the heat exchanger to capture both the latent heat and the sensible heat from the steam condensate. The result is an incredibly efficient system for generating hot water from steam.

Shell & coil heat exchangers, like the Cooney Thermo-Pack, are an evolution in heat exchanger design. They offer compact designs, improved thermal efficiency, quicker response times, easier maintenance, and increased durability. These advantages make shell & coil units a valuable consideration for any facility needing reliable and efficient thermal energy transfer.

Factors to Consider When Selecting a Steam to Water Heat Exchanger

Selecting the right heat exchanger for your facility is a decision that should be made with careful consideration of several factors. These include the materials and construction, maintenance requirements, efficiency levels, and the unit’s footprint. Let’s delve into each of these aspects.

Materials and Construction

When it comes to the construction of heat exchangers, the choice of material is crucial. For instance, the Cooney Thermo-Pack, uses fully welded, electropolished 316L stainless steel. This material choice is less prone to corrosion, ensuring the durability and longevity of the unit. On the other hand, some heat exchangers may use carbon steel, which, while robust, can be more susceptible to corrosion and pitting. Therefore, considering the material used in the construction of the heat exchanger is vital in assessing its lifespan and performance.

Maintenance

Maintenance requirements are another key factor to consider when choosing a heat exchanger. Some heat exchangers, like those with U-tube designs, require regular maintenance to prevent scale and debris buildup. In contrast, the Thermo-Pack heat exchanger does not have a tube sheet and rolled tubes that can loosen and cause failure, potentially reducing maintenance needs. Hence, understanding the maintenance requirements of a heat exchanger can help you anticipate potential costs and labor needs down the line.

Efficiency

Efficiency levels can vary significantly across different types of heat exchangers. The Thermo-Pack claims 10-15% energy savings compared to traditional shell & tube heat exchangers thanks to it’s condensate subcooling features. Understanding these efficiency levels can help you make an informed decision about which heat exchanger will offer the most cost-effective performance for your facility.

To better understand the potential energy savings that a Thermo-Pack can offer over a traditional tube bundle heat exchanger, we invite you to take advantage of our free steam energy analysis.

Space and Footprint

Lastly, the physical space that a heat exchanger occupies is an important consideration, especially in facilities with tight mechanical rooms. For instance, the Thermo-Pack heat exchanger, with its compact vertical design, can easily fit into confined spaces. In contrast, some heat exchangers may require increased piping and components, potentially making it challenging to incorporate into existing setups. Considering the footprint of a heat exchanger is crucial in assessing whether it will be a good fit for your facility.

In conclusion, selecting the right steam to water heat exchanger involves balancing several factors. By considering the materials and construction, maintenance requirements, efficiency levels, and the unit’s footprint, you’ll be well-equipped to make an informed decision that suits your specific needs. At Cooney Engineered Solutions, we’re here to help guide you through this process, ensuring you find the perfect solution for your facility.

Thermo-Pack Shell and Coil Heat Exchanger Skid

Are you looking for a reliable, efficient solution for your water heating needs? Discover the Cooney Thermo-Pack steam to water heat exchanger skid. With its compact design, it’s perfect for tight spaces. Its cutting-edge shell & coil technology ensures maximum energy utilization, leading to significant savings on your energy costs.

But there’s more to Cooney Thermo-Pack than just efficiency. It’s built with the highest quality materials for durability and minimal maintenance. Our friendly and knowledgeable team is ready to guide you every step of the way, ensuring that you get the most out of this innovative solution.