What is Causing Delays and Price Increases?

Labor Shortages

In the United States, there is a manufacturing skills gap that could potentially leave 2.1 million jobs unfilled by twenty-thirty (2030), according to Deloitte and the Manufacturing Institute. U.S. manufacturers experience trouble sourcing skilled laborers. Thirty-six percent (36%) of manufacturers believe it is harder to find workers today, compared to 2018, despite a much higher unemployment rate. With fewer employees working, positive COVID-19 results and mandated 2-week quarantines can quickly slow lead times and cause bottlenecks. Quarantine delays affect all parts of the supply chain including, sourcing raw materials, manufacturing, shipping, and distribution.

Material Shortages

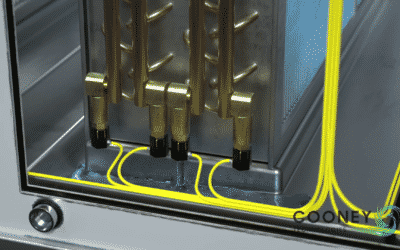

Increasing Demand for Copper & Steel

KITCO Copper 1 Year as of 11/8/2021

In the HVAC industry, copper is a valuable raw material required in heat transfer. This base metal has experienced an increase in demand, thanks to its need in green energy projects, electric cars, and so many items we use daily (pipes, washing machines, etc.). Current mining and recycling of copper struggle to meet the boom in demand, while strikes in Chilean mines drive the cost even higher stateside. Many manufactures of HVAC coils are unable to source copper fin stock until August of 2022!

The steel mills are also struggling to keep up with demand. Oil & gas industries that are heavily dependent on steel have experienced skyrocketing demand for steel as the economy reopens and travel resumes. Last year two big hitters in the steel-making industry merged, essentially making the steel industry a duopoly. This duopoly leaves little incentive to increase steel production and lower prices. Some industry analysts see rising steel costs settling by the end of the year, while others expect this could continue for the next two years – especially when the microchip shortage ends, creating a boom in automotive production. This is why it is important to place your orders now to avoid increasing costs and delayed lead times.

Other Material Shortages

While copper is the most prevalent material shortage in the HVAC industry, other materials in the manufacturing process have led to increased lead time and pricing. Lumber shortages and the inability to source 2×4’s for crating and shipping added 2-3 days to lead times. Thankfully, the industry is starting to see some materials, like lumber, come back into stock.

Shipping Industry

From the cargo ship incident in the Suez Canal to the shortage of truck drivers, the shipping and logistics industry faces significant delays and challenges. A lack of laborers due to quarantines can cause a chain reaction of delays. When a cargo ship faces a setback in unloading time, it further adds to the lead time of those goods and the goods for the next shipment. Coil manufactures are reporting the highest number of freight damage claims in history. The lack of skilled operators in terminals and increased shipping rush demands are to suspected to be the culprit of the freight damage claims.

What can you do to combat increased prices and lead times?

Act Quick

To work around longer than average lead times, consider placing your orders soon. By ordering early, you’ll also lock in your price to avoid any potential spikes that may happen in the metals market.

Consider Alternative Materials

With the high price and scarcity of copper, alternative options for coil materials may be an option depending on your application. For coils with copper used for corrosion protection, an alternative could be aluminum fins with an e-coating. Our coil selection experts can help to optimize your HVAC coil to meet performance and suggest material options.

Critical Facilities Back-Up Equipment

For facilities where a down heating and ventilation system is not an option, order spare parts for the critical areas of your facility to have on hand in case of an emergency.

The impact of COVID-19 continues to impact all industries. As time goes on, we expect an improvement in lead times and material sourcing. Give us a call today at (610)-783-1136 for updates on materials, lead times, and expedite options.