In hospitals and other large facilities, maintenance teams know the drill: every few months, systems must be shut down so fouled or scaled heat exchangers can be cleaned.

Tube bundles get pulled. Gaskets fail. Labor hours add up.

These steam-to-water heat exchangers are supposed to deliver reliable heating and domestic hot water. But traditional shell-and-tube designs often demand constant attention and eat into already tight maintenance schedules.

It’s one of the most common frustrations we hear from facility engineers. And it’s one of the problems Thermo-Pack was built to solve.

The Real Cost of Traditional Shell-and-Tube Units

Hidden costs stack up quickly:

-

Routine cleanings that tie up maintenance teams.

-

Lost heating capacity and occupant comfort during downtime.

-

Pinhole leaks, tube failures, and gasket replacements.

Traditional exchangers get the job done… until they don’t. When systems operate with poor or hard water quality, corrosion and scale shorten life expectancy and reduce energy efficiency.

How Thermo-Pack Solves It

Thermo-Pack eliminates the weak points that plague shell-and-tube exchangers.

Key advantages:

-

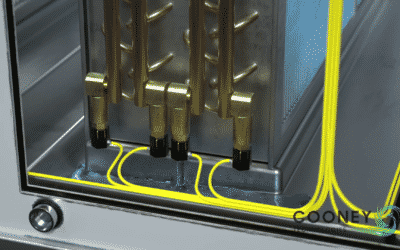

Fully welded 316L stainless steel shell & coil have no gaskets or tubes to pull.

-

Cross-counterflow design subcools condensate to recover 10–15% more energy.

-

Self-scouring flow paths minimize fouling and scale buildup.

-

Compact vertical design perfect for retrofits and tight mechanical rooms.

Together, these features reduce maintenance demands and improve uptime, which is critical for hospitals and mission-critical facilities.

What About Hard Water?

Hard water is unavoidable in many systems, but Thermo-Pack handles it better. 316L stainless steel resists corrosion and mineral scaling far more effectively than carbon steel or copper. Combined with standard water treatment or side-stream filtration, the exchanger stays clean longer and maintains high thermal performance.

Results You Can Measure

Facilities that replace shell-and-tube units with Thermo-Pack see measurable benefits:

-

10–15% more energy recovered via cross-counterflow design.

-

Fewer maintenance shutdowns and longer service life.

-

5-year heat exchanger warranty — confidence built in.

In short: less maintenance, more uptime, and lower total cost of ownership.

Conclusion

Hospitals and mission-critical facilities can’t afford unpredictable heat or emergency maintenance.

Thermo-Pack was designed for those environments, engineered to deliver consistent performance, lower maintenance costs, and peace of mind.

If your facility still relies on a shell-and-tube exchanger, it may be time to upgrade to a system that works as hard as your team does.

What makes Thermo-Pack different from a shell-and-tube heat exchanger?

Both designs transfer heat from steam to water — but they do it in very different ways.

| Feature | Shell-and-Tube | Shell-and-Coil (Thermo-Pack) |

|---|---|---|

| Construction | Uses a large bundle of straight metal tubes mounted inside a shell. Each end is sealed with gaskets and bolted covers. | Uses a continuous helical coil welded inside a pressure shell. No gaskets, no flanges, and no removable parts. |

| Maintenance | Requires periodic teardown to pull and clean tube bundles. Each tube must be brushed manually, which is labor-intensive and time-consuming. | Fully welded 316L stainless-steel coil design eliminates tube pulling. Self-scouring flow paths reduce fouling and scaling. |

| Leak Points | Multiple gasketed joints and tube sheets are prone to leaks and failures over time. | All-welded construction removes gasketed joints, preventing leaks and extending service life. |

| Energy Efficiency | Parallel flow paths limit condensate subcooling and heat recovery. | Cross-counterflow coil design subcools condensate, recovering 10–15% more usable energy. |

| Size & Installation | Typically horizontal, long, and heavy — difficult to install or replace in tight spaces. | Compact, vertical configuration fits small mechanical rooms and is ideal for retrofits. |

Thermo-Pack’s shell-and-coil design replaces the complex, leak-prone tube bundle with a single, fully welded 316L stainless-steel coil. The result is a compact, maintenance-free, energy-efficient heat exchanger that’s ideal for hospitals, universities, and other mission-critical facilities where reliability matters most.

How often does a Thermo-Pack need to be cleaned?

Unlike shell-and-tube units that require disassembly and tube-by-tube cleaning, Thermo-Pack can be cleaned in place without removing it from the system.

If performance decreases or pressure drop increases, light mineral scale may have built up inside the coil. Cleaning is simple:

1. Flush the heat exchanger with a compatible cleaning solution that’s safe for stainless steel

2. No removal required. Thermo-Pack can be flushed in place if isolation valves and bypass piping are provided.

3. After flushing, thoroughly rinse the unit to remove all cleaning residues before returning it to service.

Cleaning a Thermo-Pack is a quick in-place flush — no tube bundles to pull, no heavy lifting, and no gasket replacements.

What applications is Thermo-Pack best suited for?

Thermo-Pack is ideal for steam-to-water heating and domestic hot water systems in:

-

Hospitals and healthcare facilities

-

Universities and K-12 campuses

-

Pharmaceutical and research labs

-

Industrial process heating

-

District energy systems

It’s designed for continuous-duty operation in mission-critical environments where uptime and reliability are essential.

How efficient is Thermo-Pack compared to a shell-and-tube exchanger?

The cross-counterflow coil design subcools condensate, recovering 10–15% more energy than traditional shell-and-tube systems.

That means lower steam consumption, reduced condensate losses, and improved overall system efficiency.