What is a Shell & Coil Heat Exchanger?

There are plenty of options in the steam to water heat exchanger market. While shell and tubes have long been seen as “old reliable”, a newer model is becoming more popular: the shell and coil type heat exchanger.

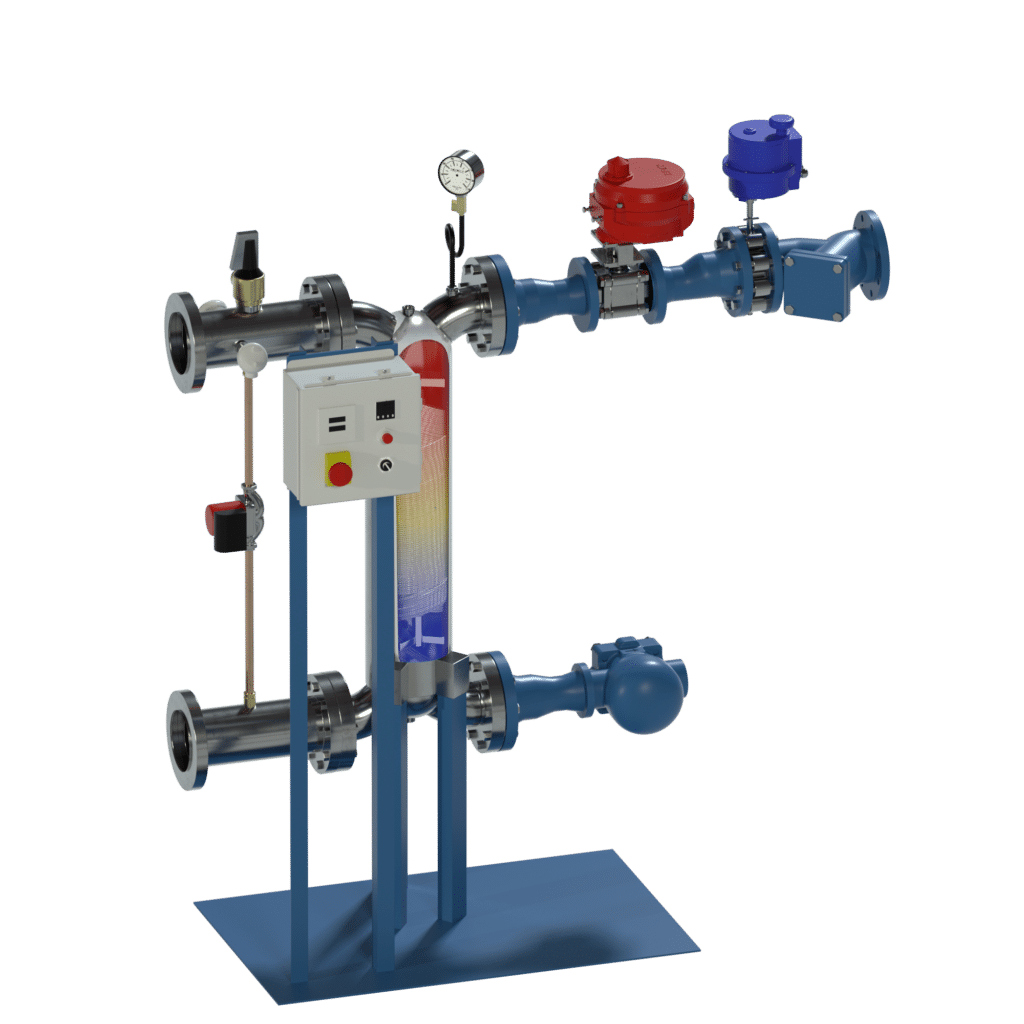

The shell & coil heat exchanger is a great alternative to the traditional shell & tube model. It features a dimple-coiled stainless steel tube, which offers greater thermal efficiency in less space as compared to straight tubes. Due to its design, it can provide efficient and reliable heating or cooling applications while taking up minimal room and providing compact, economical solutions.

Why Choose a Shell & Coil Over a Shell & Tube

Why choose a shell & coil over a shell & tube? Here we’ll discuss three reasons why this type of exchanger can be a great choice for your facility.

Energy Savings – Greater Thermal Efficiency

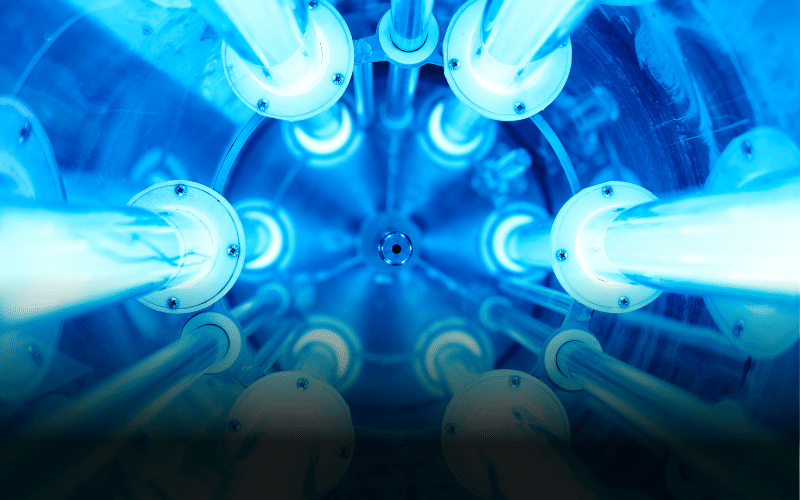

The closely packed, helically corrugated tubes of a shell & coil heat exchanger are positioned in a criss-cross pattern that allows for a high heat transfer surface area.

This technology is the most efficient way to generate hot water from steam due to its ability to utilize cross-counterflow subcooling – capturing the latent heat of the steam as well as sensible heat from the steam condensate.

The thermal efficiency of a shell & coil is far greater than that of a typical shell & tube heat exchanger. This results in lower energy costs and a faster payback period on your investment. Packaged shell and coil heat exchangers, like the Cooney Thermo-Pack can save facilities 10-15% on energy compared to a traditional shell & tube while eliminating flash steam losses.

Space Requirements

If you’ve ever been inside a mechanical room, you know they are tight and space is valuable. When choosing a replacement product, the footprint of the new product should be considered.

Shell and tube heat exchangers are most commonly configured in a horizontal position and depending on your heat load, they can get quite large – taking up valuable floor space.

JAD shell & coil heat exchangers feature a compact vertical design. This configuration gives the heat exchangers a small footprint, requiring less installation space which can help lower installation costs.

Ease of Maintenance

The total cost of ownership should be taken into account when choosing a heat exchanger. There are several things to consider: initial purchase price, installation costs and maintenance costs. A Shell and coil heat exchanger can offer a lower total cost of ownership due to its robust design and fewer parts that require periodic maintenance.

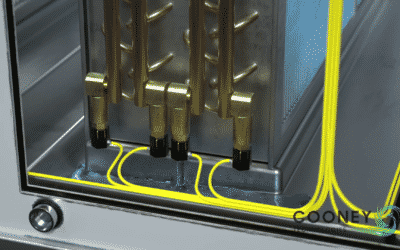

Both shell & tube and shell & coil heat exchangers require maintenance, but the stainless steel 316L welded construction of a JAD shell & coil offers some advantages over traditional materials such as carbon steel commonly used in shell & tubes. Shell & coil technology has fewer welded joints compared to tube bundles, reducing the possibility of leaks over time.

Stainless steel is much less susceptible to corrosion than its counterparts, meaning that it requires little to no maintenance – a huge plus when thinking about long-term cost savings. The shell & coil design also offers the added advantage of uniform heat transfer, reducing erosion and scaling in the tubes which can lead to costly maintenance.

The Bottom Line

When considering energy efficiency, space requirements, and maintenance costs, a shell & coil heat exchanger is an excellent choice for steam to water heat exchanger systems.

Overall, if you’re looking for a compact heat transfer device that optimizes energy efficiency while maximizing space savings, a shell & coil heat exchanger is the way to go. With its easy installation and maintenance requirements, it’s an ideal option for any number of commercial and industrial applications.

Packaged Shell & Coil Heat Exchangers

With its proven performance and reliable construction, the Thermo-Pack offers unmatched energy savings and a fast return on investment.

It’s easy to install and requires minimal maintenance, making it an ideal solution for any hot water heat exchanger application.

By utilizing shell & coil technology, the Thermo-Pack can provide energy efficiencies up to 10-15% greater than traditional shell & tube exchangers while eliminating flash steam losses.

The small footprint of this product also ensures that space requirements are minimized while increasing operational efficiency.