If you manage a hospital or campus hot water system, you already know how tricky Legionella prevention can be. Flushing lines, checking temperatures, tracking reports… it’s a lot.

Now there’s an easier way to add another layer of protection. The Cooney Thermo-Pack can be equipped with Bio-Kill™ UV, an integrated ultraviolet chamber that continuously inactivates bacteria before it reaches your taps. No chemicals, no extra tanks, and no added complexity. It’s a simple way to strengthen your water management program and stay compliant with ASHRAE 188 and 514.

Why Hot Water Systems Need Active Legionella Protection

Even well-maintained hot water systems can become breeding grounds for Legionella bacteria, especially in storage tanks, long pipe runs, or systems with inconsistent temperatures.

Traditional control methods like chlorination or thermal disinfection require frequent monitoring, downtime, and added complexity.

As new standards (ASHRAE 514, ASHRAE 188, and CMS S&C 17-30) raise expectations for water management programs, facilities are searching for built-in solutions that are simple, proven, and continuous.

What Is Bio-Kill™ and How It Works

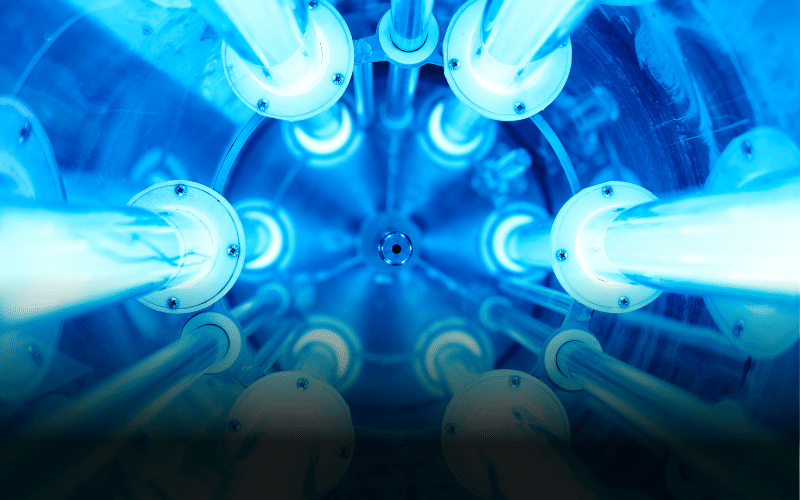

Bio-Kill™ is an integrated UV disinfection chamber designed to fit seamlessly into the Thermo-Pack shell-and-coil heat exchanger skid. As water passes through the stainless-steel chamber, high-output, low-pressure UV-C lamps target and inactivate Legionella, E. coli, viruses, protozoa, and chlorine-resistant pathogens.

Bio-Kill™ is an integrated UV disinfection chamber designed to fit seamlessly into the Thermo-Pack shell-and-coil heat exchanger skid. As water passes through the stainless-steel chamber, high-output, low-pressure UV-C lamps target and inactivate Legionella, E. coli, viruses, protozoa, and chlorine-resistant pathogens.

Because UV inactivates microorganisms at the DNA level, pathogens can’t replicate or cause infection. This provides constant, in-line protection for the facility’s water loop.

Proven UV-C Disinfection Technology

- Clinically proven with 13+ years of Legionella-free performance at major healthcare facilities, including the University of Virginia Hospital

- Chemical-free – no residuals, taste, or by-products

- Each Bio-Kill™ chamber is engineered and sized to provide the correct UV dwell time as water passes through—without slowing flow or requiring a separate contact tank.

- Continuous monitoring through control panel, alerts maintenance when lamps should be replaced. Option built-in sensors track UV intensity and can be tied into a building automation system.

- 316L stainless-steel chamber is corrosion-resistant and built for long-term reliability.

Key Benefits for Facilities and Engineers

Continuous Protection

Disinfection happens every second the system runs.

Simple Maintenance

No chemicals to add or mix. Only replace UV bulbs one time a year.

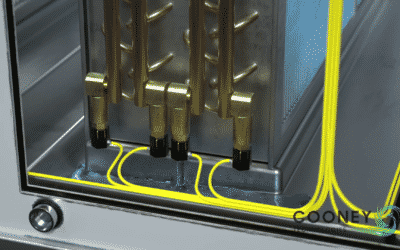

Thermo-Pack Skid Integration

Bio-Kill mounts onto the Thermo-Pack skid for a streamlined, plug-and-play solution.

Engineered Dwell Time

Each UV chamber is designed and sized to achieve the required exposure dose while maintaining full system flow — no added tanks or downtime.

Supports Water Management Plans

Stay aligned with ASHRAE 188 & 514 water management plans effortlessly with point of gerneration legionella protection.

Lifetime Performance Guarantee

Your system will perform as designed for its entire service life. It’s our way of taking the risk off your shoulders and ensuring your UV protection keeps doing its job, year after yea

Supporting ASHRAE and CMS Compliance

ASHRAE 188 and the new 514 standard require facilities to develop a water management program to control Legionella and other pathogens.

Thermo-Packs’ Bio-Kill system helps meet those expectations by providing a documented, measurable method of control at the point where hot water is generated.

Because it’s fully integrated with the Thermo-Pack system, Bio-Kill eliminates the need for extra tanks, extra chemicals, or separate maintenance protocols. That makes it easier for engineers to design compliant systems and for facilities to maintain them over time.

When to Specify Thermo-Pack with Bio-Kill™

Facilities Choose Thermo-Pack with Bio-Kill when:

-

Designing new healthcare or university facilities that must meet ASHRAE 188/514 or CMS S&C 17-30 requirements.

-

Retrofitting aging domestic or heating hot water systems to reduce risk of Legionella outbreaks.

-

Looking to replace chemical treatment systems with a cleaner, more sustainable approach.

-

Seeking to simplify hot water management without compromising safety or uptime.

Whether you’re replacing an existing heat exchanger or specifying new equipment, the Bio-Kill option adds peace of mind and long-term protection.

Get Started – Talk to an Engineer

Bio-Kill is available now as an optional feature on new Thermo-Pack systems or as a retrofit module for select existing installations.

Our engineering team can help determine the best configuration for your facility’s water quality, flow rates, and compliance needs.

→ Contact an Engineer to discuss your application or request more information.

Get Started with Bio-Kill™ UV

Download the brochure or connect with an engineer to explore your options.Get Started with Bio-Kill™ UV

Email an Engineer

Give us a Call

Key Takeaways

-

New Bio-Kill™ option, built-in UV disinfection for Thermo-Pack.

-

Continuous protection inactivates Legionella, E. coli, and other pathogens.

-

No chemicals or tanks, just a simple chamber mounted to the Thermo-Pack water side inlet for plug-and-play simplicity.

-

ASHRAE 188 & 514 aligned, supports compliance with CMS water management guidelines.

-

UV is proven technology, with over 13 years of Legionella-free results in hospital applications.

Common Questions About Bio-Kill

Discover answers to the most common questions about our innovative Bio-Kill™ technology, designed to enhance water safety and compliance.

Can Bio-Kill Be Integrated Into Existing Systems?

Yes, Bio-Kill can often be retrofitted into existing Thermo-Pack systems. Our engineering team will evaluate your setup to ensure compatibility and optimal performance.

Does Bio-Kill Eliminate the Need for Chemicals?

It can reduce or eliminate the need for chemical disinfection, depending on system design and water quality goals.