When it comes to critical facilities like hospitals, schools, and universities, reliable hot water delivery isn’t optional, it’s mission-critical. Yet many facility managers continue to rely on aging shell & tube heat exchangers that quietly drain budgets, rack up labor hours, and fail at the worst possible time.

If you’ve ever scrambled for an emergency rental, paid overtime for maintenance staff, or struggled to retrofit bulky equipment into a tight mechanical room, you know firsthand: heat exchanger maintenance costs more than you think.

The True Cost of “Keeping It Running”

At first glance, sticking with existing shell & tube heat exchangers seems cost-effective. After all, replacing equipment requires capital. But the hidden costs of maintenance and downtime add up quickly.

Labor Hours

Routine cleaning, tube sheet repairs, and leak fixes eat away at maintenance staff time. With many facilities already short-staffed, every extra hour matters.

Downtime

Lost operational time impacts everyone, from patients in hospitals to students in schools.

Emergency Rentals

When an exchanger fails, facilities often scramble for costly temporary solutions to keep hot water flowing.

Unplanned Expenses

Unexpected failures rarely happen during regular hours, meaning overtime charges and contractor call-ins.

Why Shell & Tube Designs Fall Short

Shell & tube exchangers have been around for decades, but their design creates maintenance headaches.

Over time, tubes loosen or leak at the tube sheet, requiring repair or replacement.

Mineral deposits build up on tubes, causing scaling and fouling. This reduces efficiency and demands frequent cleaning.

Their horizontal footprint makes them difficult to install or replace in older facilities with limited space.

These problems aren’t just technical nuisances — they’re budget drains that leave facilities frustrated and contractors pressed for time.

A Smarter Solution: The Thermo-Pack Shell & Coil

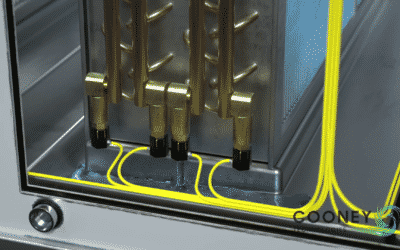

The Cooney Thermo-Pack is a modern alternative built around shell & coil technology. Its design directly addresses the pain points of shell & tube:

Fully Welded 316L Stainless Steel means no tube sheets to fail, dramatically reducing leak risk.

-

Instead of rigid tubes, Thermo-Pack uses coils that naturally flex with temperature changes. This movement helps shed mineral deposits during operation, creating a self-cleaning effect that reduces fouling and extends service life.

- Water and steam flow in opposite directions across the coil, ensuring maximum heat transfer efficiency. This approach also helps prevent thermal shock, protecting equipment from sudden temperature fluctuations that can lead to premature failures.

-

Thermo-Pack delivers 10–12% energy savings compared to traditional shell & tube designs.

-

Backed by a 5-year heat exchanger warranty for your peace of mind.

For facility managers, that means fewer service calls and emergencies. For contractors, it means faster installs and fewer callbacks.

The Contractor’s Advantage

Mechanical contractors also benefit when facilities choose Thermo-Pack. With its compact design and reduced piping complications, installations move faster, even in the tightest mechanical rooms. Contractors spend less time troubleshooting and more time delivering successful, on-time projects.

That translates into stronger client relationships, fewer emergency callbacks, and a reputation for installing systems that last.

The Takeaway

Heat exchanger maintenance and failures don’t just cause inconvenience, they create cascading costs that affect budgets, operations, and people.

Sticking with outdated systems means signing up for more of the same: leaks, downtime, and constant maintenance.

The Cooney Thermo-Pack flips the equation. By investing in a low-maintenance, energy-efficient shell & coil design with flexible, self-cleaning coils and cross-counterflow protection against thermal shock, facilities save on labor, avoid costly rentals, and gain peace of mind knowing their hot water systems will perform when it matters most.